My daily commuter and sometimes training bike is a KHS Flite 900. Not a popular bike but actually a fantastic bike for the price. I love it.

It comes with a PF BB30 bottom bracket. It's not the 42mm BB shell version where the bearing press right into the Shell (with cir clips). It's the 46mm BB shell version where the bearings press into a nylon sleeve that presses into the shell. There's a nylon sleeve that joins the two outer sleeves, in the middle of the BB shell. The BB has been in for about a year

I have the nifty Park Tool BB30 bearing removal tool (like a screwdriver with a T on the end rather than the point) and I've watched all sorts of You-tube videos. And I'm a mechanical engineer.

Firstly, I can't believe that the friction fit BB30 was ever developed as a solution. It's just a bad idea on so many levels IMHO. That said, it's on my bike and I have to deal with it now.

I have used the tool and managed to get one side out after much beating with a hammer and profanities. The other side (drive side) appears to be at one with the universe and after 4 hours of teaching the entire neighbourhood new words, it's moved about 0.1mm, and I'm being generous. I've beat the crap out of it. I've used penetration oil to try and get it out, and so on. I even manage to completely shag the bearing, tearing out the inner sleeve along with the captive balls. Only the outer sleeve, that is firmly in contact with the nylon sleeve, remains.

I've had people suggest heat, but as the frame is carbon, I'm nervous about doing that.

If it makes any difference, the crankset is FSA. There is no info on the nylon or bearings, but I'd expect that to be FSA as well?

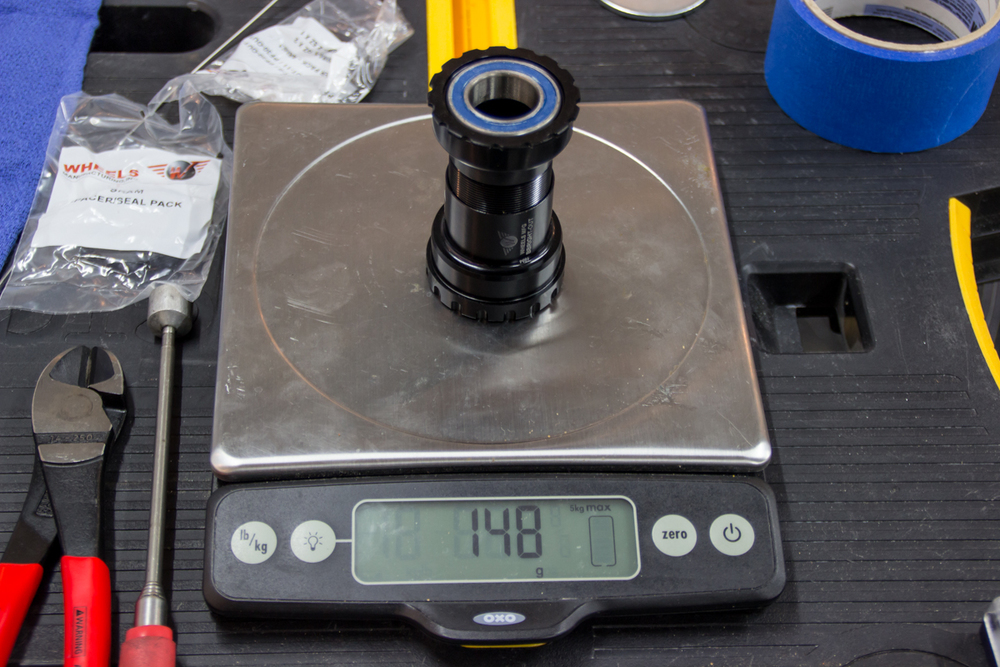

Also, for the next installation, I've looked at these guys and I like the idea of the screw fit PFBB30 versions http://wheelsmfg.com/...bottom-brackets.html Anyone have any experience with them or have better ideas for replacements?

My questions are:

any suggestions for getting the nylon sleeve and remainder of the bearing out of the BB shell?

any suggestions for a replacement item so next time I can do it in the 10 minutes they show on You Tube?

TriDork

"Happiness is a myth. All you can hope for is to get laid once in a while, drunk once in a while and to eat chocolate every day"

It comes with a PF BB30 bottom bracket. It's not the 42mm BB shell version where the bearing press right into the Shell (with cir clips). It's the 46mm BB shell version where the bearings press into a nylon sleeve that presses into the shell. There's a nylon sleeve that joins the two outer sleeves, in the middle of the BB shell. The BB has been in for about a year

I have the nifty Park Tool BB30 bearing removal tool (like a screwdriver with a T on the end rather than the point) and I've watched all sorts of You-tube videos. And I'm a mechanical engineer.

Firstly, I can't believe that the friction fit BB30 was ever developed as a solution. It's just a bad idea on so many levels IMHO. That said, it's on my bike and I have to deal with it now.

I have used the tool and managed to get one side out after much beating with a hammer and profanities. The other side (drive side) appears to be at one with the universe and after 4 hours of teaching the entire neighbourhood new words, it's moved about 0.1mm, and I'm being generous. I've beat the crap out of it. I've used penetration oil to try and get it out, and so on. I even manage to completely shag the bearing, tearing out the inner sleeve along with the captive balls. Only the outer sleeve, that is firmly in contact with the nylon sleeve, remains.

I've had people suggest heat, but as the frame is carbon, I'm nervous about doing that.

If it makes any difference, the crankset is FSA. There is no info on the nylon or bearings, but I'd expect that to be FSA as well?

Also, for the next installation, I've looked at these guys and I like the idea of the screw fit PFBB30 versions http://wheelsmfg.com/...bottom-brackets.html Anyone have any experience with them or have better ideas for replacements?

My questions are:

any suggestions for getting the nylon sleeve and remainder of the bearing out of the BB shell?

any suggestions for a replacement item so next time I can do it in the 10 minutes they show on You Tube?

TriDork

"Happiness is a myth. All you can hope for is to get laid once in a while, drunk once in a while and to eat chocolate every day"