I screwed up…I had to disassemble my bottom bracket to replace my inner ring.

I neglected to take note/photo of WHERE the Wave Ring was installed. Drive Side or Non-Drive Side

Here are some photos if helpful.

https://smfr.box.com/s/j61fw1yw83xruzosdencvweoffi7voly

https://smfr.box.com/s/voeach98zqkpuq2b5h4vnlunq0k5jh45

https://smfr.box.com/s/zcmq26k75eo0r8zkjohsyw82yezdkp18

Should wave ring go on Drive Side or Non-Drive Side?

I’m not an expert, but i put mine on the non-drive side so that I can actually see it. When you have everything tight, you want the wave washer to be almost flat. If it’s on the drive side I don’t know that you’d be able to see it.

edit: the above is what i do on my bb386 bike. Looking at images on google, it appears like GXP manuals show the wave washer on the DS.

I would do a Google search for the installation instructions.

I screwed up…I had to disassemble my bottom bracket to replace my inner ring.

I neglected to take note/photo of WHERE the Wave Ring was installed. Drive Side or Non-Drive Side

Here are some photos if helpful.

https://smfr.box.com/s/j61fw1yw83xruzosdencvweoffi7voly

https://smfr.box.com/s/voeach98zqkpuq2b5h4vnlunq0k5jh45

https://smfr.box.com/s/zcmq26k75eo0r8zkjohsyw82yezdkp18

Should wave ring go on Drive Side or Non-Drive Side?

Is this a GXP crankset? Looks like maybe a SC fin in bottom of video. If yes, then the waive washer goes on the DS as it is there to preload the bearing on that side as the NDS spindle step clamps the NDS bearing between the step and inside of the NDS crank arm.

For 30mm spindle cranks installations wo a preload nut it shouldn’t matter which side the wave washer is installed.

I screwed up…I had to disassemble my bottom bracket to replace my inner ring.

I neglected to take note/photo of WHERE the Wave Ring was installed. Drive Side or Non-Drive Side

Here are some photos if helpful.

https://smfr.box.com/s/j61fw1yw83xruzosdencvweoffi7voly

https://smfr.box.com/s/voeach98zqkpuq2b5h4vnlunq0k5jh45

https://smfr.box.com/s/zcmq26k75eo0r8zkjohsyw82yezdkp18

Should wave ring go on Drive Side or Non-Drive Side?

Non drive side between the crank arm and the dust cover

That looks like a SRAM/Quarq wave washer and it goes in the the drive side between the spider and the bottom bracket.

That looks like a SRAM/Quarq wave washer and it goes in the the drive side between the spider and the bottom bracket.

I’d defer to this since I didn’t realize it wasn’t FSA

.

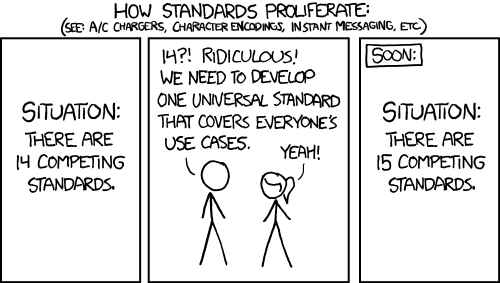

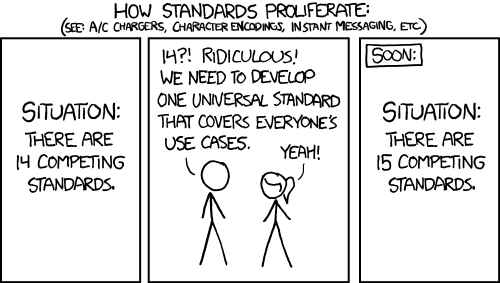

…and this is why the BB situation is pissing me off.

That looks like a SRAM/Quarq wave washer and it goes in the the drive side between the spider and the bottom bracket.

Thanks eve-home !!! Yes…seems to fit nice without wobble.

It does not free spin very good…and I can kinda hear some resistance maybe inside or near the ends of the drive side and non-drive side. think I will take it all apart again and clean and re-grease.

Recommendations for what kinda grease I should be using in the bottom bracket?

Where are you going to put the grease?

BBs are all sealed bearings. You should not need grease to get it to spin good. Something is off in the way you installed it.

For 30mm spindle cranks installations wo a preload nut it shouldn’t matter which side the wave washer is installed.

While installing it on the drive side of a BB30/386 crank wouldn’t affect how the BB functioned, it would slightly change the chainline and require a front derailleur adjustment if it had originally been on the non-drive side…

Where are you going to put the grease?

I understand the bearings are sealed.

Currently there is fare amount of greases in and around the bearing and the shaft. blackish, nasty stuff.

Thought I would clean it all, and put new grease in and around everything.???

New grease won’t do anything.

New grease won’t do anything.

thanks for the help, guidance, and input.

This forum is a GREAT resource for a guy like me…learning bike engineering, maintenance, and bike DIY stuff

again…I’m not an expert. I put waterproof grease on the spindle, threads, and a light coating on the bearings. My BB on my gravel bike lasted 4 years with a bunch of wet and nasty races mixed in, deep water crossings, etc.

I can’t say whether or not the grease helped, but I will keep doing it because it certainly didn’t seem to hurt.

For 30mm spindle cranks installations wo a preload nut it shouldn’t matter which side the wave washer is installed.

While installing it on the drive side of a BB30/386 crank wouldn’t affect how the BB functioned, it would slightly change the chainline and require a front derailleur adjustment if it had originally been on the non-drive side…

If it is compressed, I doubt it, but when I’ve used a wave washer on BBRight installs I do put it on the NDS as another poster mentioned for visually verifying compression.

For 30mm spindle cranks installations wo a preload nut it shouldn’t matter which side the wave washer is installed.

While installing it on the drive side of a BB30/386 crank wouldn’t affect how the BB functioned, it would slightly change the chainline and require a front derailleur adjustment if it had originally been on the non-drive side…

If it is compressed, I doubt it, but when I’ve used a wave washer on BBRight installs I do put it on the NDS as another poster mentioned for visually verifying compression.

According to the instructions of every BB I’ve assembled that uses a wave washer, you are not supposed to completely flatten the washer.

- Install wave washer spring over spindle on left side of BB shell. Caution: Do not completely flatten the wave spring washer. Clearance between non-drive arm and bottom bracket is 1.5-2.0mm.

So if the wave washer is installed on the drive side, you’re shifting the chainrings over 1.5-2mm, which would usually require readjustment of the front derailleur in order to prevent rubbing and/or overshifting. If you disregard those instructions, and you’re able to completely flatten the washer, then it would only be a fraction of a mm difference…

So if the wave washer is installed on the drive side, you’re shifting the chainrings over 1.5-2mm,

wave washer is only about 0.5mm

.

So if the wave washer is installed on the drive side, you’re shifting the chainrings over 1.5-2mm,

wave washer is only about 0.5mm

As noted when I wrote that if “you’re able to completely flatten the washer, then it would only be a fraction of a mm difference.” If you follow the installation instructions correctly (at least all the ones I’ve seen), the washer is only supposed to be partially compressed…