My first business was making hardware for aero testing. Just like many devices now, we had a pressure sensor to measure wind speed. We went to a wind tunnel to validate our system and ended up running into this one challenge we couldn’t overcome. We eventually removed the sensor and switched to a software only solution, to be used in an indoor velodrome.

When I worked at Specialized there was a phase were I had a company a month reaching out to me claiming to have finally solved outdoor aero testing, by adding a wind speed sensor of various designs. With all of them I shared the number one technical challenge I saw for them to solve, and I haven’t seen anybody solve it yet. If you know of a company that has this figured out, let me know, I’d love to meet them.

Heres the issue:

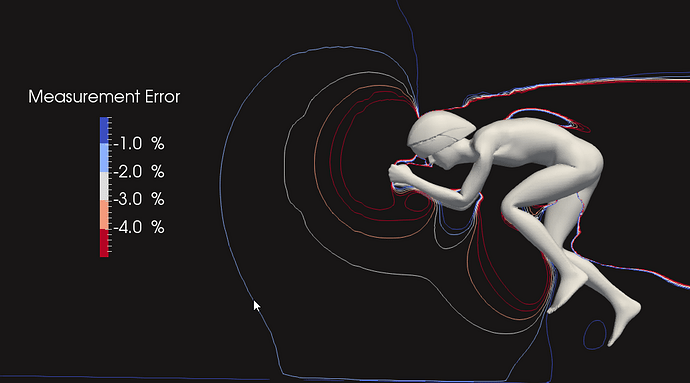

The presence of the rider locally affects the air flow. Depending on the location of the wind speed sensor, it could read speeds lower or higher than the freestream speed. How much you can see in the image below

The red line closest to the rider surrounds the area where the sensor would be off by 5%. The next line shows an error of 4% and so on, the last blue line, highlighted by my mouse cursor shows how far away from the rider you would have to place the sensor to incur an error of less than 1%.

Now these sensors are being used on planes and F1 cars successfully, and the solution is to calibrate it to account for the presence of the vehicle. But here is the catch:

The main thing we want to use the data for is to inform bike fit decisions, so we want to be able to move the athlete around. But moving the athlete, also moves the “upstream pressure bubble”.

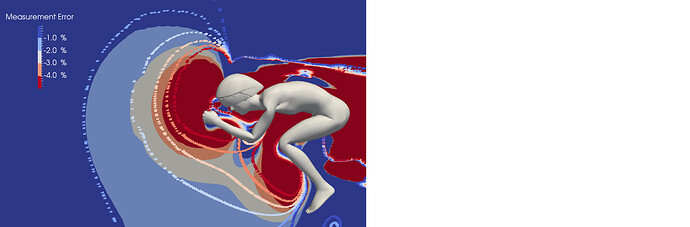

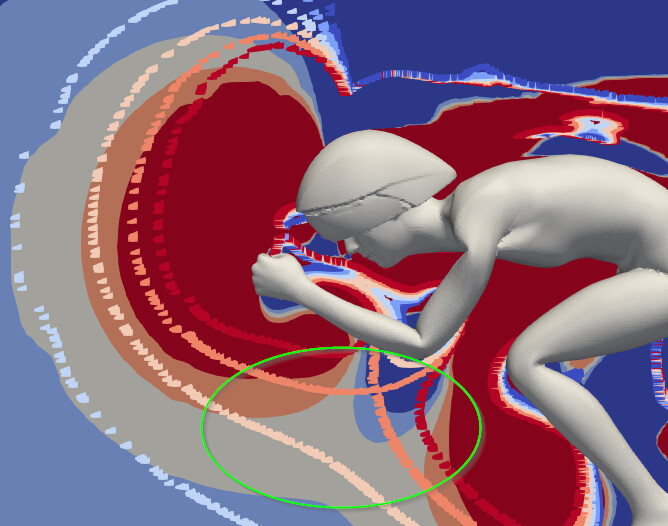

This image shows the same outlines again, but as shaded areas. What I did, was load in the wind speed data from another bike position as well, and visualized those outlines through colored dots.

For many of the most common sensor locations, you can see that the difference in wind speed measurement can be as high as 4% and is often higher than 1%. This means that our change in athlete position caused a change in wind speed measurement, that goes into our CdA/Aero calculation. A 1% error in wind speed would translate to roughly a 3% error in CdA calculation, or 6ish counts, bigger than the difference between many fit changes we want to tell apart.

What is bad is that this error source is perfectly confounded with what we want to measure, so more repeats don’t help and there is no easy way to tell if a change in measured CdA comes from improved aerodynamics or from moving the low speed air zone more over the speed sensor.

Do you know of any company that has solved this issue? How did they do it?

UPDATE: Based on @marcag s feedback I checked out Aero Sensor and their approach. I think its a good practical solution in even and relatively low wind conditions. Thanks!