Originally published at: Zipp Ride Ready - Slowtwitch News

The two most interesting shifts in corporate strategy within what we can acceptably call the “fitness” industry have occurred at Garmin and SRAM, both of which have embraced Apple’s “ecosystem” approach to product development. I wrote about Garmin’s shift previously, and alluded to the similar shift that SRAM has undergone over that same time. SRAM certainly no longer resembles the SRAM of 2006/07, when the first RED groupset was introduced. But perhaps even more interestingly, SRAM is increasingly diverging in important ways from Shimano. Di2 is a “feature” of certain Shimano groupsets. AXS is a foundational pillar of everything that SRAM does. Some of this is possible because, like Garmin, SRAM has acquired many of the pieces of its ecosystem. Shimano has always been loathe to grow through acquisition, and its only acquisition in recent memory – of Pearl Izumi – likely did little to convince it to change in that regard. But SRAM has basically acquired almost all of what we think of today as “SRAM.” Sachs (chains) in 1997, RockShox (suspension) in 2002, Truvativ (cranks and BBs) and Avid (brakes) in 2004, Zipp in 2007, and Quarq – their most important acquisition – in 2011. Numerous more acquisitions have followed, some of which I didn’t even know about (Velotron and Shockwiz; the latter of which I didn’t realize was an independent company).

The Quarq acquisition was, to me, the most important, not because of the product, but because of the people. In particular, Jim Meyer, Quarq’s founder. Jim is now the “Director of Digital Product” at SRAM. And, at this point, there’s less that isn’t digital in SRAM’s offering than is. Digital is everything to SRAM. The AXS mobile app serves as an important hub, especially with the number of batteries in the system. And those products that aren’t digital should be generally viewed as “not yet.” Flight Attendant – the latest RockShox advancement that combines power data and real time shock tuning (see SRAM’s 2018 acquisition of ShockWiz) to modify your suspension in real time. Brakes are currently the only complete system that has no electronic component, and while I don’t see wireless and hoseless brakes arriving anytime soon – your brakes not working because your battery is dead is not really a viable option, it’s certainly not impossible; especially for TT brakes, a wireless master cylinder would open up quite a few interesting frame options…

This systemic approach to product design sometimes requires partner buy-in. The AXS Transmission – currently only found on Eagle MTB drivetrains, but which is surely coming to Road and Gravel at some point – needed frame manufacturers to adopt the UDH (Universal Derailleur Hanger) standard. But SRAM mostly owns all the requisite pieces now to fully design a system that never requires – or, in some cases, even allows for – the end user to leave their ecosystem.

As important as Zipp was an acquisition, giving SRAM both a world class domestic composites manufacturing team and facility as well as a major distribution hub – the majority of SRAM’s US inventory now leaves from Zipp’s Indiana HQ, it had largely remained separate from this systemic approach to design. Zipp wheels largely existed in the “old fashioned” world of cycling, where most parts were fairly interchangeable. That’s starting to change a bit, with Zipp-specific variants of Quarq’s TyreWiz coming standard on certain Zipp MTB wheels. But the most dramatic changes are the most recent ones – the introduction of Zipp’s new Vector tires manufactured by Goodyear and Zipp’s Ride Ready program, designed to get those tires and wheels (and SRAM cassettes and Avid rotors) straight into the hands of their customers.

The Ride Ready program speaks to the degree to which SRAM has become a software company. While it’s a fairly straightforward shopping cart app, it’s more that SRAM sees Ride Ready as yet another way that software can enable their customers and bring them into – or further into – the SRAM ecosystem. But really, it’s the Vector tire line that highlights the degree to which SRAM has become an ecosystem company most of all. Ride Ready only really makes sense because of everything SRAM can offer to the end user – the perfect-match Vector tires, the ability to provide relevant tire pressure information to users via the AXS app and website, the central location of the Indianapolis warehouse allowing them to add sealant to the wheels and tires immediately before shipping, and to add additional configuration options in response to user demand in a matter of days – if not hours. I spoke about the Ride Ready program with Ride Ready program manager Mike Vittorio and wheel product manager Nathan Schickel, who has been at Zipp for almost 20 years and with whom I worked on a number of products – including Zipp’s Vuka Stealth aerobar – when I was sponsored by them.

The Goodyear Partnership

While Zipp could have introduced such a program earlier, the partnership with Goodyear makes that proposition make much more sense, because it’s really hard to tell this story effectively without tires. These are tires that are wholly optimized for Zipp’s wheels, and also makes it more congruous with the larger thrust of SRAMs evolution as a company. It’s not that Zipp is sending you complete wheels. It’s that they are sending you a system that they have optimized for you. I asked Zipp if they imagine a specific tire for every wheel in their lineup. I expected the answer to be, “No.” But it was a resounding, “Yes Absolutely.” Every wheel can have a tire – or tires (the 303 has both a 30mm and 35mm option, for example) – optimized specifically for its width, depth, and overall shape along with intended usage. Zipp calls this Total System Efficiency. The recently introduced 303XPLR demonstrates this in dramatic fashion, with its massive 32mm internal width, introduced unsurprisingly alongside a new Goodyear gravel tire meant specifically for this wheel. That wheelset was available via Ride Ready the day that it launched.

The partnership with Goodyear is also helping Zipp emphasize that Total System Efficiency applies not only to what Zipp has traditionally been known for – aerodynamics – but also what riders are increasingly concerned with, namely rolling resistance (Crr) and grip. Grip, especially, is one of those things that I think is too often an afterthought. But grip is the thing that I appreciate most of all when I’m actually riding. Tires that grip well are just that much more fun to ride. By partnering with Goodyear, Zipp was able to create tires that are aerodynamically optimal – the 30mm variant of the Vector is understandably faster than the 35mm variant of the Vector, but each tire is optimized for its width and for the wheel. But Zipp is also clearly trying to shift away, at least ever so slightly from trying to assess their wheels by any single metric. The system is fastest. As a whole. Zipp did clarify that even if tires are optimized for specific wheels, the measured differences are quite small. L3GION has been riding the 30R NSW tires on their 454s with great success.

The tires being “generally good” is an explicit design choice. In the pro tour, teams will typically have four different tires – a Classics tire, a Road Race tire, a Time Trial tire, and a Rain tire. The SW series is designed to fill both the Classics and, critically, the Rain tire at once. In particular, the larger size option gives teams much more flexibility for say, a wet and cobbled course, arguably the most challenging conditions imaginable. That these same tires happen to also be quite aerodynamic is a bonus. Zipp has yet to introduce a TT specific tire – I’d imagine that will come with the 858 and, likely, a dedicated rear for the Super9. But even just being able to use the same tire for Classics and Rain is a huge win. While I didn’t get to test out wet weather grip – I do love California summers!, I am also not sure how much I really would want to push the envelope here in pursuit of journalistic excellence. I’m happy to take Zipp’s word for it, especially given how good the dry grip is. Grip is a consistent story, and possibly the first time I can remember really hearing about how important it is, though I can say that my race tire of choice for most of my pro career – the Specialized Turbo Cotton – had superb grip along with incredible Crr, something that more than made up for slightly less than ideal aerodynamics. That same story – that the tire needs to do everything well, even if it gives up a bit in one particular area – was something Zipp’s product management team kept coming back to.

In one example, the Vector NSW gives up 3w in Crr (on average, across a range of road surfaces) to the Continental GP5000 but gains back 2w in aerodynamics (on average, across a range of yaws). If you note that Continental still comes out ahead by 1w in this case, you’re right. But that’s where Zipp focuses on durability – race tires don’t need to be bombproof, but they cannot be fragile – and especially on grip, which is a function of both the rubber and the shape of the tread cap and also the structure of the sidewall plies, both of which are explicitly designed to be optimal when mounted on Zipp’s wheels. I also expect that Goodyear’s casings will improve over time, leading to a reduction in Crr. Goodyear knows rubber. Zipp knows aerodynamics. So it’s not surprising the tires shine in these areas. But bicycle specific tire casings take time, and Goodyear is certainly playing some amount of catch up here to Vittoria and Continental, the current leaders in low Crr casings.

The rubber – Goodyear calls it “Dynamic UHP Rubber” and you will also find variants of it on their car tires – is a highlight. Especially with the massive footprint of a wide tire at low pressure, I found myself having to re-learn how fast I could take some of the corners I’ve taken countless times on some of my regular routes. I’ve found myself riding these tires more like I ride my mountain bike, leaning the bike way over – much more than I ever would have thought appropriate on a road bike. I haven’t yet put enough miles on these wheels to really put meaningful wear on the tires, but after a few hundred miles, they still look as new. Not a single nick or cut. And I certainly haven’t babied them. Especially if you live somewhere that has less than ideal pavement, these tires are truly superb for training. Even some of the roughest stretches of road – of which there are fewer and fewer, thanks infrastructure! – were very muted. Pure slicks are never going to be great off-road tires, but low pressure and the resulting large contact patch makes for tires that are very capable on any kind of fire road. This setup is perfect for any sort of “all road” race, which was my hope and expectation.

Nathan said Zipp first started speaking with Goodyear in 2020/2021. Zipp had been working with Hutchinson previously on tires like the RT28 and the Tangente G40 gravel tire. These were good tires, but Zipp thought they could be better, in particular in the way that they could optimize the system as a whole. Nathan said that Zipp briefly considered trying to do tires themselves, but the cost of an adequate tire factory to achieve their standards would likely have cost more than Zipp itself is worth as a business. Partnering just made more sense, and in particular, partnering with Goodyear made a lot of sense. In a contrast with what had been the development process to date, where Zipp would provide a list of requirements and manufacturers (Zipp has worked with both Vittoria, who made Zipp’s first ever Tangente tires, and Hutchinson on their tires) would come back some months later with the tire that they believed met those requirements, the process with Goodyear was much more iterative. They tried multiple casings during development, eventually settling on one that worked the best across all metrics. Tubeless technology has certainly made puncture resistance less of a concern, but tire durability still matters. I found it especially interesting that even though Goodyear is only very recently focusing on tires, they have a dedicated factory that only does bike tires. And this is actually quite unique in the industry. Continental, for example, makes its bike tires in the same factories where it makes car tires. This focus on cycling was an important differentiator for Zipp, and it was a key part of why they felt they were able to do so much iterative development.

Tire collaborations are heavily informed by automotive precedence. The Vector tires are, fundamentally, Goodyear tires. Goodyear owns the IP. But it is designed specifically for Zipp’s wheels. In automotive parlance, this is called a “fitment series.” Car makers will approach a tire manufacturer to make an OEM tire to spec. That tire can obviously be run on any car that takes a tire in that same size. But the particular compound, tread pattern, et cetera will all be designed to fit the wants of a given car. In this case, because Goodyear is still relatively new to cycling, Zipp led on the aerodynamics. Notably, Nathan said with these latest wheels and tires, Zipp has effectively managed to eliminate stall at any realistically achievable yaw angle – even very extreme ones. He pointed to extensive crosswind testing that Zipp had done on the Queen K highway in Kona to get a sense of just how extreme yaw angles could get. With wider rims and tires, hookless rims, and tire casings designed specifically for those rims, the aerodynamics package is just that much more stable at high yaw, which leads to both faster speeds and better handling. This was the early promise of the Firecrest wheelset when it was first introduced, but it has taken tires to fully realize its potential.

The Ride Ready Experience

Walking through the entire Ride Ready process, I selected the Zipp 303 paired with the 35mm Vector SW tire. The 303 is Zipp’s do it all wheel, and at roughly half the price of the 353 NSW ($2381 with a slightly heavier 1270 – Force – level cassette vs $4770 with a top of the line 1290 – RED – level cassette), it’s a much more compelling offering. Is the 353 faster? I’d say almost certainly yes. But as with the early Zed-tech wheels, I’ve always thought it was really a very marginal pickup for a relatively high cost increase. The variable cross section NSW rims are substantially more complex to manufacture, so the cost is not unwarranted. I love Zipp’s regular wheels – and have ridden nothing else since 2008 – and have never found them wanting. I can unequivocally recommend the 303s. They are just fantastic wheels. I’d have a harder time recommending the 353s as a do-it-all-wheelset at the premium price. Especially on this site. The 303s are more likely to be your do it all wheelset for mixed-road races, training, and certainly are very capable race wheels. But for this site’s audience, if I was to ever recommend an NSW wheel, it would almost certainly be the 858 where the additional crosswind stability and aerodynamic speed of the variable cross section rim is likely to be more compelling to those folks on the margin. I never rode an NSW in my decade long tenure as a Zipp athlete, as when they were introduced, it was firstly as a rim-brake-only wheelset and I had just made the switch to what was – at the time – an outlier riding disc brakes for the last year of my pro career.

The setup I selected – 303 with Vector SW 35 – is what I consider the perfect Belgian Waffle setup. The iconic Belgian Waffle Ride – now series of rides – challenges expectations about what a road bike is capable of. I did the original BWR in 2018 on a set of Zipp’s new-at-the-time Tangente 28s, which measured at 30mm on the 303s at the time – with hooked rims, unlike the hookless variant offered currently. I rode them at 60psi front/rear, which was fine, but I definitely was much more nervous on the dirt than I would have been on the Vector 35s at 45psi/48psi. While it’s impossible to effectively simulate what it’s like to race something like BWR, I did quite enjoy being able to ride on the shoulder equally easily whether it was dirt or asphalt during testing. I did need to put on my own 10-44 cassette – that cassette, whether in 1×12 or the 10-46 1×13 variant – is really the perfect do it all cassette. I was a bit surprised Zipp didn’t offer this as a part of Ride Ready, but they also said that they hadn’t really thought about rides like BWR when setting up the Ride Ready offerings. They were quick to point out, however, that if there was sufficient demand, adding the 10-44 (12s) or 10-46 (13s) offerings to the 303 wheelset was something that could be done in a matter of hours, done on a computer in an upstairs office and able to be implemented immediately on the assembly line downstairs – those cassettes are already in stock in the Indianapolis warehouse adjacent to the Zipp factory. This was when I realized that the wheels you buy really are built for you. There were some other options I would like to see – brass nipples for one; I’ve never understood why people have traded the durability of brass nipples for the weight savings of aluminum ones, but that’s admittedly the start of a long tangent. I also was surprised to not see any rotor options – I normally ran 140mm/140mm rotors, which is admittedly non-standard, but that came from riding 24mm tires when I first got on disc brakes, and I felt 160s were too easy to lock up. But 160mm-fr/140mm-rr is pretty standard, but that wasn’t an option. 160/160 was the only option, though again, these are options that could be added easily.

The tires are filled with OrangeSeal, because Zipp has found that to be the most reliable sealant. While Zipp advertises that all you need to do when you get the wheels is to bed in the rotors, in my experience that does assume that you are already running those exact same rotors. In my case, I had to switch the mounting brackets for my calipers from 140mm → 160mm. But based on historical experience, I’d also say you will – if you’re not running SRAM’s Paceline rotors already – also need to deal with rotor alignment. Disc caliper tolerances are such that different rotors and different hub shells can cause some small amount of rubbing. I wouldn’t say this is necessarily a given – certainly the pro tour races all manage to have neutral wheel support without issue, but I also wouldn’t be surprised if a little bit of tweaking was required, especially if you are coming from non-Zipp wheels and non-SRAM rotors. Both because I was changing from Zipp → Zipp and because I had to completely remount my brakes to switch from 140 → 160 mm rotors, I can’t offer any direct experience here as to whether or not pumping up the tires was all I had to do. But certainly avoiding dealing with the mess of sealant and mounting tires was a welcome relief. The wheels came to me with just under 30psi in them. Not quite enough to ride, but certainly enough that there was no worry of sealant leaking around the bead.

Sealant functionality and longevity tends to be inversely proportional. Orange Seal can be expected to last at least three months, and maybe as long as six depending on weather. But I also know that most tubeless riders are less diligent than they maybe should be about replenishing sealant. Some never do. And because flats are just generally less of a problem with tubeless, this is probably fine. The particulars of sealants are certainly well outside the scope of this article, except to say that Orange Seal is a very good sealant. And since the sealant is applied literally within days of you receiving your wheels, you can be confident that it will last as long as possible.

While there were some additional options I would have liked, I did appreciate the simplicity of picking a wheel and then choosing a tire, selecting yes for rotors, and then picking from either of two cassette sizes in two “tiers” (Force or RED equivalent). From there it was the very standard Shop.com checkout process – Zipp gave me a coupon code to cover the cost of the wheelset for this article – and the wheels showed up about three days later.

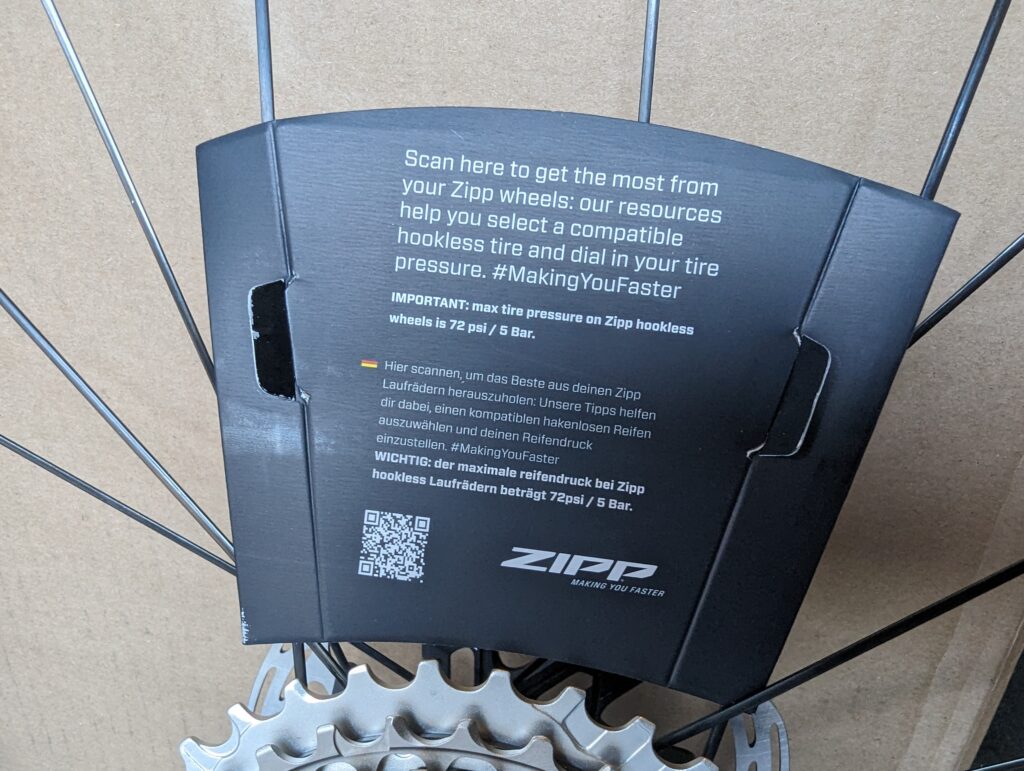

Unboxing the wheels, I was impressed with just how seamless the transition from tire to wheel is. It’s hard, even in pictures, to appreciate how perfectly the tire mates to the rim. And, of course, the aerodynamic story is something is essentially something you have to take on faith. But you can have that much more confidence in it because of the one big problem SRAM solves for you – tire pressure. I suspect because of changes to the wheels over time and a desire to avoid an overly long dropdown list, SRAM still makes you pick the bead type and the bead width rather than allowing you to pick a specific Zipp wheel. But you do get in addition to the generic casing options two specific ones for the Vector tires. This is where the system comes into play. Rather than picking a generic and rather subjective “casing” for your tire, you just specify which specific Goodyear Vector model you have. And then SRAM’s tire pressure guide – available both on the web and in the AXS app – gives you the exact pressure for your setup and riding style. In my case, that ended up being 45psi in the front and 48psi in the rear. Like most – probably all – “correct” tire pressures, this feels much too low, especially if you have any real experience riding on 21mm (or skinnier) tires at 120psi+. But then you get out of the road and forget about it and worry less about the quality of pavement or even if the road is pavement.

Ride Ready’s simplicity is an integral part of the narrative around Total System Efficiency. Engineering concepts like Crr and CdA are things that riders increasingly understand conceptually, but they are still difficult to parse out while riding. According to Schickel, tires always should have been wider and run at lower pressure. It really took disc brakes to really unlock that possibility. Hookless tubeless rims have helped make the experience better. But there’s still a battle against psychology – what “feels” fast (high-pressures) is typically the opposite of what actually is fast. Even on the track, pressures as much as half of what was typical are the norm, because a wood velodrome is often not quite as smooth as it would appear. As with aerodynamics a decade or two ago, convincing cyclists that “smooth is fast” remains an ongoing challenge. I think that’s where the focus on grip can help. It’s much easier to feel how much more grip you have with a big contact patch than it is to “feel” lower rolling resistance. It’s also just more fun.

Zipp has always tried to do a good job of informing their potential customers. They are a company that believes that a well informed customer will appreciate the benefit of Zipp wheels and will feel better about paying their premium price. But that process still asked a lot of customers, especially given that mounting and seating tubeless tires can be a major pain. I’ve never needed anything but a floor pump with my tubeless road wheels, but I do have an air compressor to make the process that much easier. Dealing with sealant is absolutely a nuisance. With tires that Zipp can confidently say are the best all around tires for their wheels, they’ve made the process that much simpler for end users, and in doing so, they provide a compelling case for joining the SRAM ecosystem. As with the new Transmission drivetrains – which do away with limit screws and a B-gap screw, using technology to make cyclists live simpler is the end goal. As the famous da Vinci saying goes, “simplicity is the ultimate sophistication.”