Originally published at: Who Is Leading the Charge with TT Bikes Front Ends? - Slowtwitch News

The more I research the history of this industry, the more I realize how Dan Empfield has influcened the bike industry as we know it today. Let’s talk about something other than stack & reach, or X&Y, or the fact that he created the first Triathlon-specific bike. I want to speak for a second about how he has always influenced front-end design; if you go back in history, you start to notice that every time a bike manufacturer wanted to go with an integrated headset, he told that individual and or company to go pound sand. He would always give many reasons for the why, but in the end, it would be the simplest reason: because it made it too difficult for the user to adjust the bike position. You would sell someone a bike and they would go get fit and well, instead of changing out a stem or adding some tilt, boom you had to take out the old metal saw and find the super glue.

We can go back and look at the companies that have taken heed of Dan’s advice and those who haven’t. Specialized, Trek, and even Cervelo all had a lot of issues with the lack of adjustability in their proprietary set-ups. All of which were justified by the wind tunnel, tests, and a “sexy-looking” bike. When disc braked bikes started to come out, Trek sort of got it right, Cervelo was 2nd, and the Specialized Shiv missed the mark altogether. What the bike manufacturers forgot about was the need for the end-user to be comfortable (comfort = fast) for the long haul of 70.3 and 140.6 distances, which is precisely what they were making those bikes for. The fight over integrated water bladders, and the design on front-end to ensure the bike could be as fast as possible in the wind tunnel, missed the mark. Marketing consumed their time and engineering efforts, skimming over comfort and adjustability.

If you go to this year’s bike count at the IRONMAN World Championships, you can see the bicycle companies that have taken heed of Dan’s suggestions and created bikes that may not be so fast in the tunnel, but offer users the experience that they were looking for when it came to adjustability and comfort.

Back to my original question and title of this article: who really is leading the charge in the aerodynamics and comfort of the front end of the bicycle? Is it the bicycle companies that are making the fastest bikes, or is it the third-party specialists that look at how the big companies are screwing the front ends up and filling those gaps? If you look at the bike count, you see the same bicycle company leading the charge over the last 20 years. Cervelo has lost the bike count only once. But that gap continues to become smaller. If you look at other companies, they have come and gone based on marketing spend, product adaptation, and bike designs that need to be revised for the end-user. What has been consistent across the board is that the front end is always massively won by third-party aero bar manufacturers, and not the stock bicycle manufacturers. These either come from good relationships with OEM partners or simply the fact that the bicycle brands screwed up the front end so badly that the end customer needed to find a better solution to become comfortable for that rider to become faster.

Just look at the current Specialized Shiv, for example. All of that time and energy in the wind tunnel testing that bike working around water hydration and internal bladder patents that, on paper, make it faster than the last one. And they made adjustments based on the feedback they got from the original. Yet the bike had zero to little tilt adjustability. In the end, Specialized got so irritated with the lack of sales from that bike that they ended up abandoning long course triathlon altogether, focusing on shorter-distance events. Not a single sponsored rider is using that bike anymore. If you go online and look at most of the Shivs being sold, they have different third-party aero bar setups. Why is this? Why didn’t Specialized work closely with an OEM spec partner that could help them with the design of that front end? Were they afraid that information about the bike was going to get leaked during development? Were they were trying to increase profitability by manufacturing the front end themselves?

I don’t know the answers to this, but what I do know is that every single time I look at that bike, I get sad. It is a speedy bike, but they just completely missed the boat on the front end which in my opinion, affected sales. By extension, it reduced Specialized’s commitment to long course triathlon (and all of triathlon as a whole).

Now, if you look at other companies that did listen to Dan’s advice and have made tremendous strides with growth, not only in triathlon, but as a brand in general:

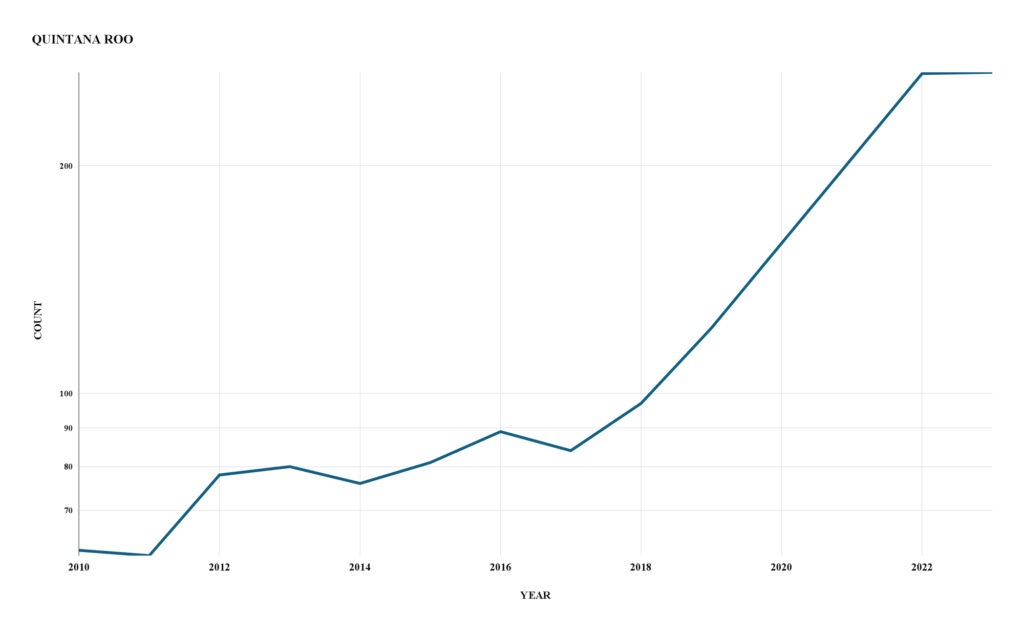

KONA bike count over the last 10 years

Quintana Roo is an example that has always worked closely with Dan, not because they have always seen eye to eye, but because they knew Dan would give them the feedback that he gained from the community as a whole, and they would take that feedback and integrate that into the design of their bikes. QR’s history has almost always been to use 3rd party integrated aero bar set ups for any of their TT bikes; they would invariably seek advice and partnerships from third-party experts to help them. This could be because these small companies like QR that I am talking about did not have the budget or desire to work on the front end themselves, but regardless of the reason they didn’t, it seems to have worked out for them in the long run.

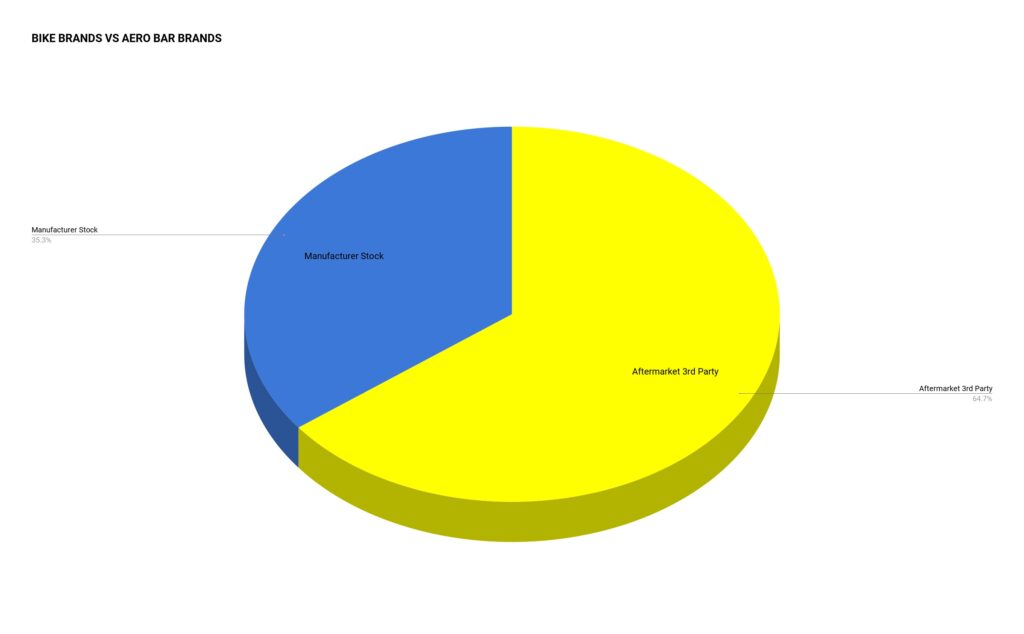

This year in Nice, we learned the same thing at the bike count: overall, third-party aero bars always win over manufactured stock aero bars that come on bikes.

When it comes to the masses, the data points to the fact that either the bike brands need to come up with better approaches to their front-end designs, or they need to work more closely with these 3rd parties that are winning the aero bar race.

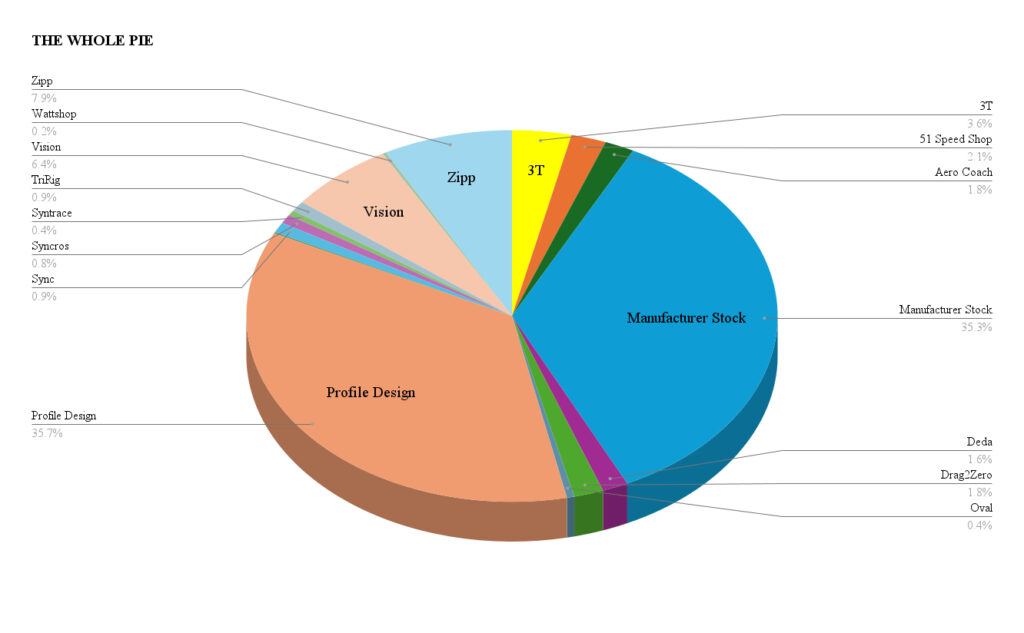

Looking at the 2024 Nice Count, only 35.3% of all bikes came with brand-manufactured front ends. 64.7% was with 3rd party OEM Partners or customers switching out for better solutions. Profile Design owned more than 1/2 of that 3rd Party result.

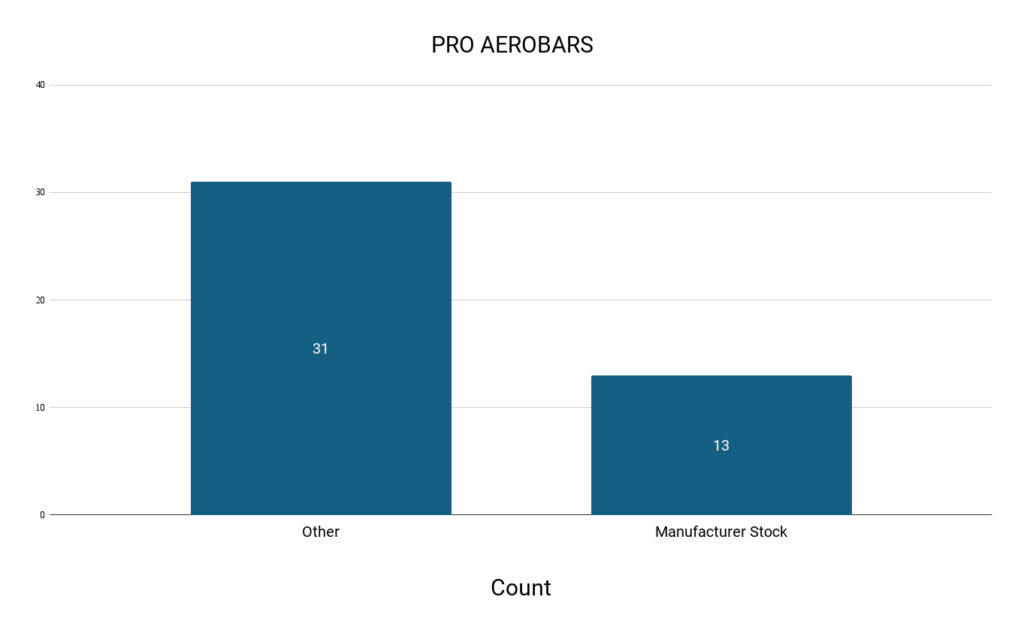

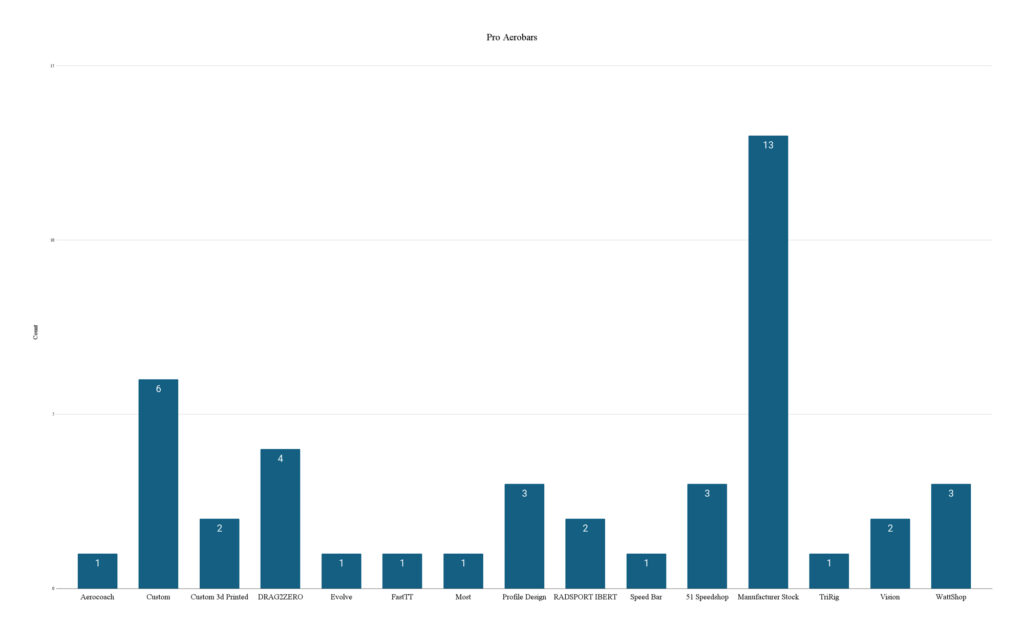

Even the pros are taking the bull by the horns and switching up the front ends.

2024 IMWC Nice, Pro Female Bikes

Is Profile Design the best? At the bottom (age group masses), it appears so, but if you look at the top (the pros), they even need to catch up if they want to continue being at the top. With all these other players in the mix, it’s becoming apparent when you are looking at purchasing your next bike, brand and frame are just one part of the thought process, followed by what bar you will put on.

Now, let’s keep one super important thing in mind: we haven’t completed the 2024 bike count yet; we are only half done. Kona is still to come, when we get all the men’s data, and then we can really start to hone in on all of the trends, including bars. I believe there’s even going to be a bigger gap between vendors. My guess is we will see a greater increase in third-party and 3D-printed bars.

This whole topic makes me think:

#1 There’s a lack of understanding that some of the big bike companies have when it comes to the front-end fit of endurance athletes.

#2 There’s an importance of specialists in the marketplace.