I’m sure there’s differences in the quality of cables and housings. So which one’s does slowtwitch recommend

Personally I use Jagwire housings and then just about any cables on my bike. I also re-cable my bikes twice a year.

How do you determine when it’s time to do that

.

Normally in the spring after the roads dry up and then about 4 weeks before my biggest race.

When cables start to look crusty and dirty, any fraying at all. Check at the shifters where the cables bend around the bar end (TT bike) or cylinders (road brifters and mountain triggers).

If any housing is kinked, it gets replaced. I haven’t done any nokon or similar segmented cables cuz I’m cheap and don’t have issues that they may solve.

Sometimes it’s subjective, I may have a shifting issue because of bad weather or some other reasons. If I ever have to lubricate a cable to get it moving it’s going to get changed before the next ride.

That’s a lot of unnecessary work.

I change out my brake cables after two years of regular riding just for peace of mind and only do the gear cables when there is friction in the system that shouldn’t be there.

Best cost considered housings and cables I have found is durace polymer inners and any big brand outer.

All cables get Shimano cable grease, a squirt of grease in every end cap before fitting to prevent corrosion and proper consideration to cable routing.

Personally I use Jagwire housings and then just about any cables on my bike. I also re-cable my bikes twice a year.

I just recabled my road bike with Jagwire Elite sealed cable systems a couple of weeks ago. I’m not sure the sealed shit is worth the effort. But it shifts and brakes fine.

Shimano PTFE cable and housing.

None of you guys find the Shimano coated cables start to shed their skin ?

WD ![]()

I tried the Yokozuna reaction kit a few years ago and really like it. Definite speed improvement with shifting and smooth. I’m not sure if I notice a difference over the stock shimano for the brake feel/power/modulation. The brake housings are very strong and I had to use a short shimano piece in the rear next to the steatpost on my road bike because it kept pushing the brake over no matter how short I made it. Brought it to a shop and they couldn’t get it to work either. Anyway, the shifting was noticeably better.

That’s a lot of unnecessary work.

I change out my brake cables after two years of regular riding just for peace of mind and only do the gear cables when there is friction in the system that shouldn’t be there.

Best cost considered housings and cables I have found is durace polymer inners and any big brand outer.

All cables get Shimano cable grease, a squirt of grease in every end cap before fitting to prevent corrosion and proper consideration to cable routing.

It’s unnecessary work to have a perfectly shifting bike all of the time?

Perhaps you don’t have the same environmental conditions that I do.

None of you guys find the Shimano coated cables start to shed their skin ?SRAM cables peel/shed too, it causes a lot of hung/delayed shifts. It usually happens at a point where the cable enters housing. I swap them out every 6 months or so. I replace the housing once a year, when I change my bar tape.

Segmented compressionless housing because it improves braking modulation and responsiveness, turns sharper corners for your TT bike cable routing, can be lengthened/shortened and basically looks amazing. I like the Jagwire stuff because it doesn’t fall off the liner and end up in a pile on the floor.

Segmented compressionless housing because it improves braking modulation and responsiveness, turns sharper corners for your TT bike cable routing, can be lengthened/shortened and basically looks amazing. I like the Jagwire stuff because it doesn’t fall off the liner and end up in a pile on the floor.

Does it improve shifting?

Does it improve shifting?

I don’t think so. I mean I just click the lever at the front and it moves from one sprocket to another back there on the cassette. I think that’s all I really expect from it, I don’t have any high hopes. I guess if it fetched me a sandwich and told me I was handsome then that would be a nice improvement, but to be fair it just changes gear in a pretty predictable and boring way. At least it doesn’t complain about doing its job, which is more than can be said for my wife. So there’s that.

None of you guys find the Shimano coated cables start to shed their skin ?

WD ![]()

If you have good cable runs, use proper end caps, cable grease and trim casing properly, then no, I have not seen any shedding issues on any cables I have fitted. And coming from a workshop situation, that’s a shitload.

New bikes that have not been prepared properly may shred for sure.

The current cables on my road bikes have been there for 3 years and everybody comments on how well they shift.

I use polymer cables on my mtb too, gears and suspension lockouts.

I have had zero problems, they seem to cope with mud, dust and rain no problems.

I think choice of how to cut outers and prepare them is critical, as is using the recommended cable grease that everybody doesn’t seem to. Most shops don’t even have it.

Do not oil them like conventional cables, they will shed for sure then.

I have seen cables on new bikes a couple of rides old that are shedding, that’s what gives them a bad reputation.

Bad runs, hurriedly cut ends and no cable grease.

None of you guys find the Shimano coated cables start to shed their skin ?

WD ![]()

If you have good cable runs, use proper end caps, cable grease and trim casing properly, then no, I have not seen any shedding issues on any cables I have fitted. And coming from a workshop situation, that’s a shitload.

New bikes that have not been prepared properly may shred for sure.

The current cables on my road bikes have been there for 3 years and everybody comments on how well they shift.

I use polymer cables on my mtb too, gears and suspension lockouts.

I have had zero problems, they seem to cope with mud, dust and rain no problems.

I think choice of how to cut outers and prepare them is critical, as is using the recommended cable grease that everybody doesn’t seem to. Most shops don’t even have it.

Do not oil them like conventional cables, they will shed for sure then.

I have seen cables on new bikes a couple of rides old that are shedding, that’s what gives them a bad reputation.

Bad runs, hurriedly cut ends and no cable grease.

We’re do I learn how to do those things. My LBS sucks and I want to learn the right way.

Good info thanks.

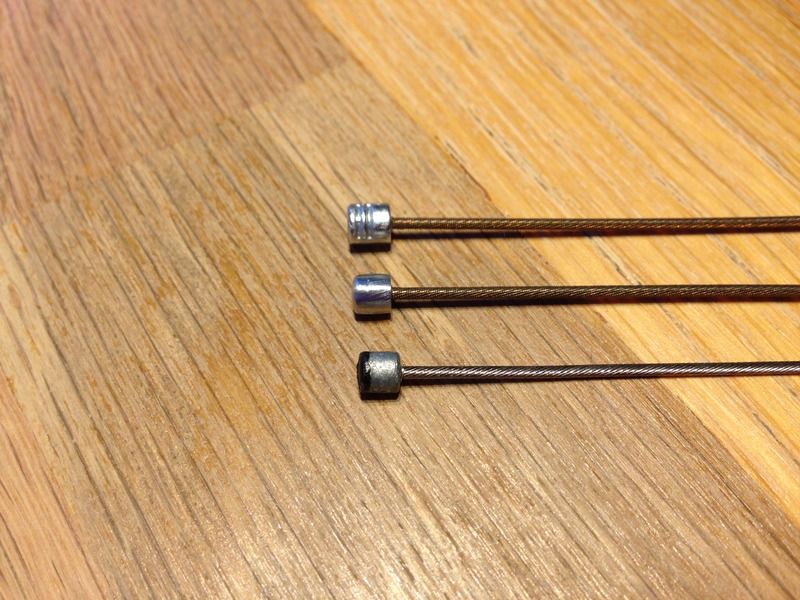

I don’t think cable end prep is my problem, here is the standard I work to :

http://img.photobucket.com/albums/0903/Peter1/MTB/DSC03851.jpg

That’s the large diameter old school XT housing.

I am pretty anal with my builds, for example this is what I did by hand to fit Shimano polymer gear cables into campag shifters :

And to ensure nice transition from frame to cable the custom Ti part replaced the standard crappy frame boss :

So, hopefully that rules out the crappy cutting / shoddy fitting part of the equation … ![]()

So what’s the special grease ?

At the moment I am using a 100% silicon grease so maybe that’s the issue ? (But it does seem to work really well on cables)

I haven’t seen the problem as bad as what the other posted added a picture of, but it’s there and it bugs me … lol

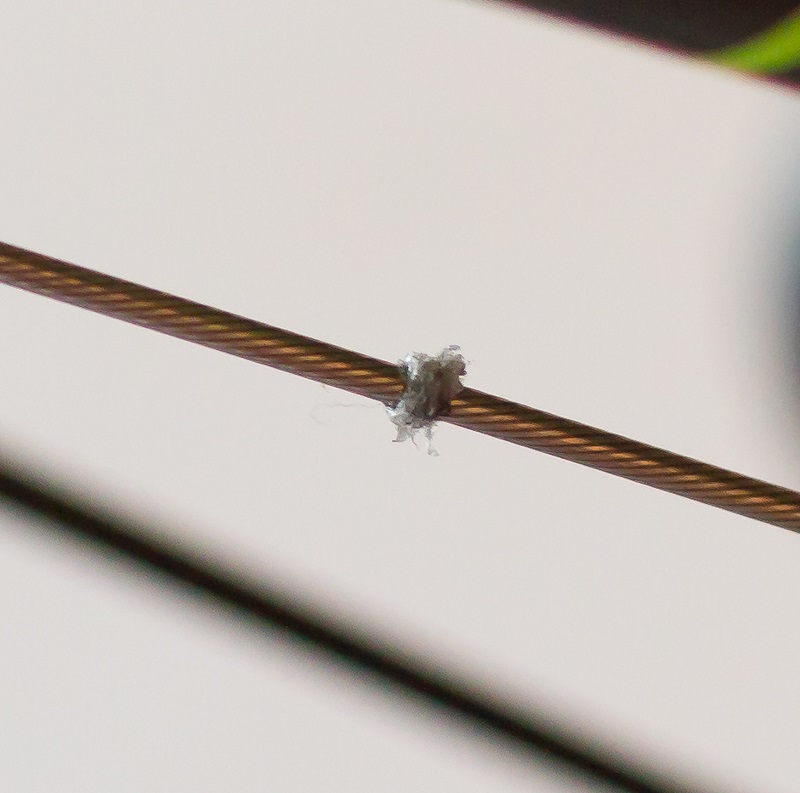

I fear there are certain areas I can’t do anything about such as where the cable enters the adjuster, you can just see it here :

Those were the first areas to show it … ![]()

The other area I can see it is on the rear mech on full shift / maximum cable exposure - even though I managed to fit the Shimano sleeved cable end to the campy mech.

My exepiaces to date :

MTB : Black Shimano cables / sleeved goodridge ends / goodridge outers.

Tri : Full durace kit / all correct ends etc.

In my experience, the old black Shimano cables are actually holding up best.

Any help / comments / advice on grease appreciated.

WD ![]()

Good info thanks.

I don’t think cable end prep is my problem, here is the standard I work to :

That’s the large diameter old school XT housing.

I am pretty anal with my builds, for example this is what I did by hand to fit Shimano polymer gear cables into campag shifters :

And to ensure nice transition from frame to cable the custom Ti part replaced the standard crappy frame boss :

So, hopefully that rules out the crappy cutting / shoddy fitting part of the equation … ![]()

So what’s the special grease ?

At the moment I am using a 100% silicon grease so maybe that’s the issue ? (But it does seem to work really well on cables)

I haven’t seen the problem as bad as what the other posted added a picture of, but it’s there and it bugs me … lol

I fear there are certain areas I can’t do anything about such as where the cable enters the adjuster, you can just see it here :

Those were the first areas to show it … ![]()

The other area I can see it is on the rear mech on full shift / maximum cable exposure - even though I managed to fit the Shimano sleeved cable end to the campy mech.

My exepiaces to date :

MTB : Black Shimano cables / sleeved goodridge ends / goodridge outers.

Tri : Full durace kit / all correct ends etc.

In my experience, the old black Shimano cables are actually holding up best.

Any help / comments / advice on grease appreciated.

WD ![]()

I googled Shimano cable grease for you, here is the first on the list.

https://www.amazon.com/Shimano-SIS-SP41-Shift-Cable-Grease/dp/B001GSSNCM

If you look at your casing prep, you will notice that the inner Teflon lining does not come completely to the end of the housing.

There is now a possibility of cable rubbing on metal.

Don’t grind it.

Heat screws up the Teflon liner.

All you need is a good set of cable cutters, make sure the end is reasonably square and shows no burs and shove a sharp spike, usually supplied as part of the cable cutters, down the end of the casing to open out the liner before fitting.

The teflon lining should be open, the casing not distorted/squashed and the Teflon lining showing at the end.

Put a squirt of grease in the endcap and fit.

Casings don’t really wear out.

I have never yet seen the Teflon liner worn through.

Really old casing may crack the outer though.

What kills casing and creates friction is water getting into the ends and then the metal strands can rust.

Rust expands the metal and narrows the casing causing friction. Hence the squirt of grease into the cable ends before fitting to help combat this.

If the casing is long enough, usually you can just cut 10mm off the end and reuse it and the rust is gone.

Don’t take the outer plastic cover off the casing like you have done, the casing can now move in the fitting and the plastic does a pretty good job of sealing the casing to the fitting when present.

The polymer cables actually have little ribs all the way along them.

This is to hold the cable grease.

Fitting without grease simply wears the ribs off and creates the problems off shedding.

Because the cables are tightly wound with the polymer coating, you can easily remove them from a new bike and refit them properly as they will not fray.

All new bikes should have the cable pulled, the endcaps checked for burs and then greased and the cables refitted with cable grease.

As far as I am concerned all bikes should have this done before they go on the display floor along with headsets greased etc.

When a cable comes into a fixture from and angle, it will also try and leave at an angle.

If the casing prep has not been done or incorrect endcaps used, the cable will rub on the side of the casing where it exits and tear up the coating.

So make sure cables run into fittings perpendicular so they leave nice and perpendicular.

Where this cannot be achieved in places like a rear derailleur that changes the geometry of the casing as it moves, use the Shimano supplied endcaps with the extended dick on it to support and guide the cable at the exit point.

No rocket science, just basic prep done to manufacturer specifications.

Thank you - I would still like to know what the shimano grease is based on … ![]()

(I don’t know your age sorry) For info, that stripped back housing is retro gold from around 1990 and is very large, it needs stripping back to fit in a boss that will actually fit a frame braze on. They were for the 2mm braided inner cables that look like wire rope. It was only posted as an example of how I finish cable outer ends.

I know the inner is a bit short on that one but it’s only because it’s a short length and pulled back, when fitted they are the right length and flared into a small funnel at the end (I normally use a cocktail stick).

I have to be honest, I am swapping my wheels for a wider set and will replace the brake cable inners at the same time (can’t have a second clamp mark on the cable !) - unless something can change my mind pretty quickly I will be fitting the standard ground stainless type … ![]()

WD ![]()

Yes, I am of the same era.

Grinding ends was good before the teflon liners came about.

Stripping back the outer cover went away with slimmer housing and plastic endcaps.

Even brake end caps that were always fitted by stripping about 5mm of the plastic changed then too.

For a while Shimano even tried to have a one housing does all and had no spiral wound casing.

These felt really smooth for braking but if they were left until they cracked the outer then it would collapse, so they quietly disappeared.

Original 8 speed STI used to have to be stripped back to fit into the shifter, no longer.

Polymer cables for gears results in massive less force for shifts, but doesn’t make much difference for brakes.

Good old stainless with Triflow works fine.