Originally published at: ENVE Foundation AR40 Wheelset: The Olive Branch to The Cycling Community - Slowtwitch News

The AR40 is ENVE’s newest Foundation wheelset and it’s what I consider the latest “olive branch” to the OEM and new consumer world for the company. If you’re not familiar with the Foundation line up, it’s ENVE’s sub-$1,500 play—designed to give you the ENVE experience (aerodynamics, ride quality, reliability and warranty) without the premium ENVE price tag (handmade is never cheap). One could think of it as the gateway drug to their more premium line up. This is why I think we will start to see these more and more.

The Numbers That Matter

| Spec | What You Get |

|---|---|

| Wheelset Weight | 1,515 g (with tape and valves, HG freehub) |

| Rim Weight | 425 g each |

| Rim Depth | 40 mm front and rear |

| Internal Width | 25 mm |

| Price | US$630 front / $770 rear |

So you’re looking at $1,400 for a full wheelset. For a carbon aero wheel from ENVE, that’s a pretty compelling number.

The Aero Story

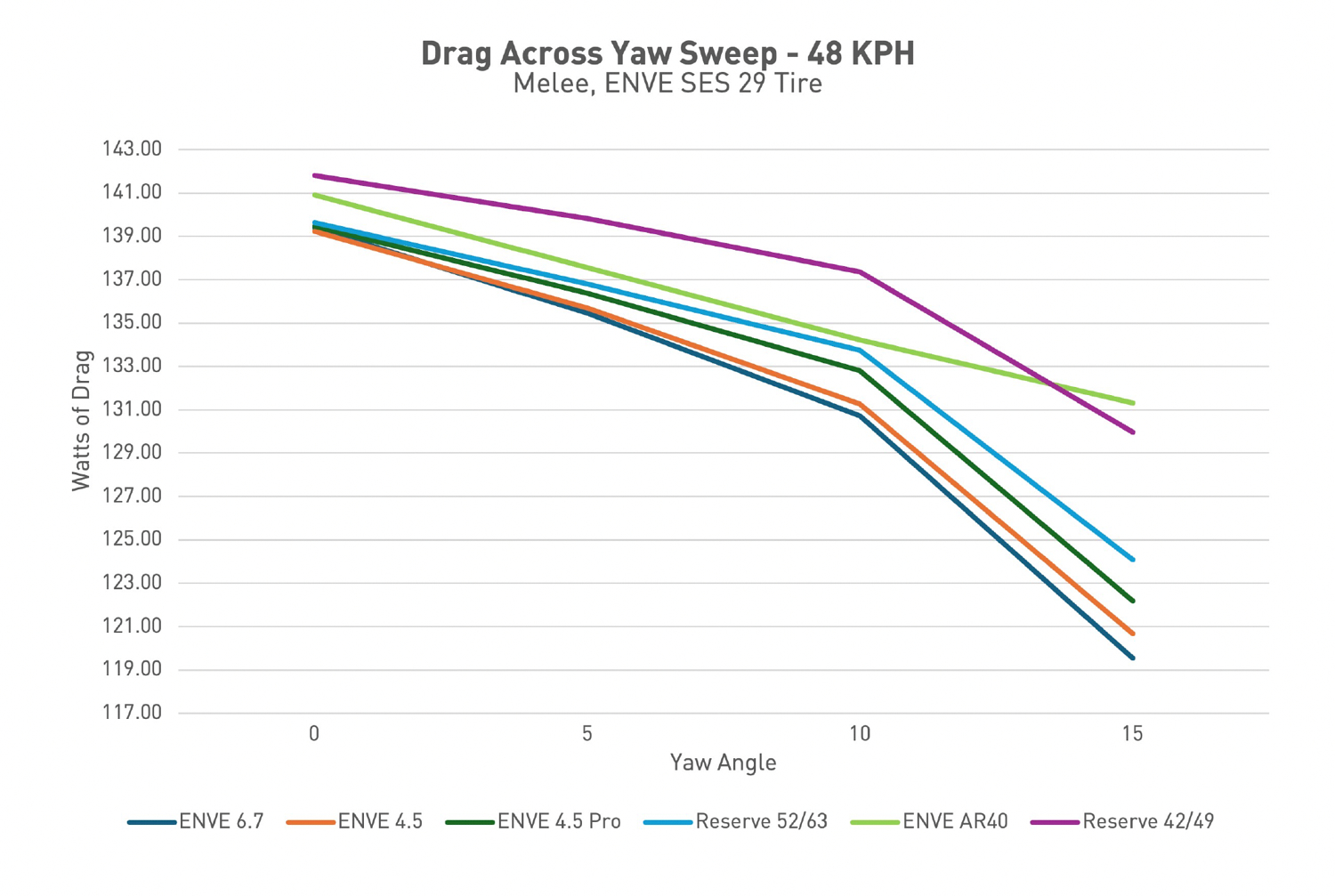

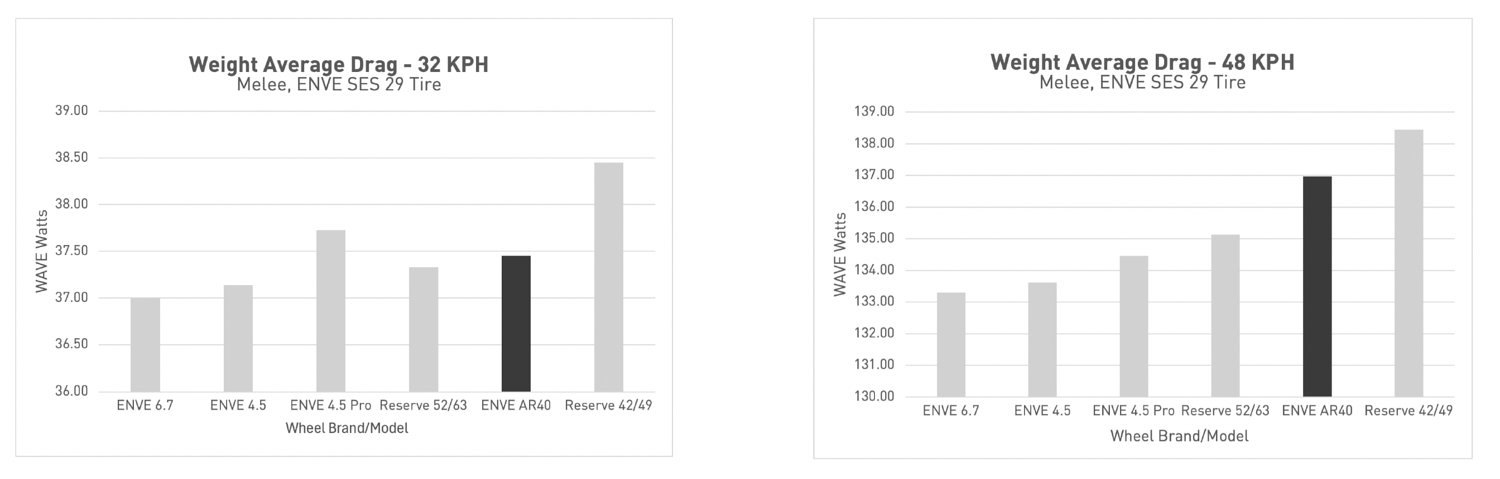

ENVE is starting to do a better job at showing the data again. They have always had it, but I do like to think that, after being asked over and over again, they did the right thing and started to show it. They tested the AR40 at the Mercedes-Benz Formula One Wind Tunnel—the same place they test the SES line. And they tested at both 20 mph/ 32 kph AND 30 mph/ 48 kph, which matters if you’re not a pro putting down 30+ mph for hours.

The rim is optimized for 29 to 30 mm tires. That’s the sweet spot where they claim the aero numbers “punch above its depth and price point.” Looking at the wind tunnel data they provided, the AR40 hangs with the more expensive options across the yaw angle sweep. And the claim is that they beat the similar Reserve wheels they compared.

Gravel Rated

While the AR40 is primarily designed for performance road usage (the aero part, for sure), ENVE has tested and qualified the wheels to their gravel standards. The 25 mm internal width supports tires all the way up to 50 mm. So, if you’re running a modern road bike with clearance for bigger rubber, or you’ve got an all-road/gravel race bike, this wheel works for both. You will want to make sure you are looking at the ENVE Tire chart that you can you can find here. That’s another reason why I can see this as a great OEM upgrade wheel for entry-level gravel bikes.

The Tech

Even though the wheel is half the price of the premium selection, it still comes with the things that ENVE just isn’t willing to give up.

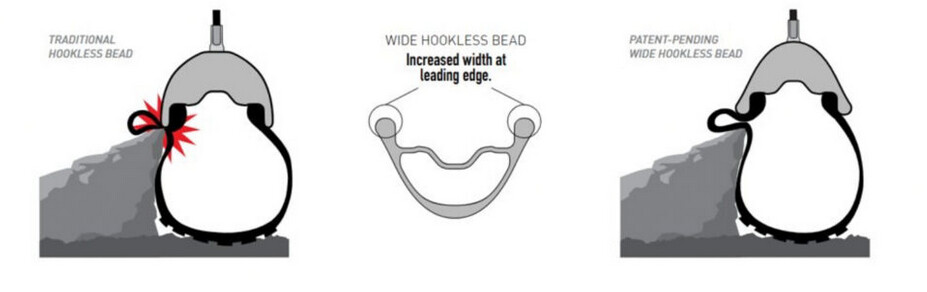

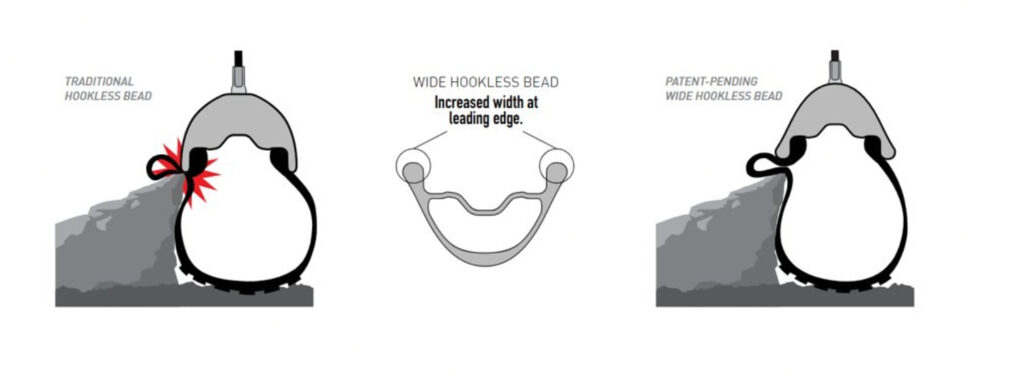

Wide Hookless Bead (Patent Pending): This is ENVE’s pinch-flat protection design. The idea is that when you hit a pothole, the wider leading edge dissipates impact energy better than a traditional hookless bead. This means fewer pinch flats, whether you’re running tubes or tubeless. Just to be clear—as the photo could be a little misleading—this “wider” is not created by the inner rim wall being at a NON 90 degree angle (straight up and down). The wider leading edge is created by an extra layer on the outside of the rim wall with beefed up carbon. (I like to think of it as a place for an object to slide off during impact.)

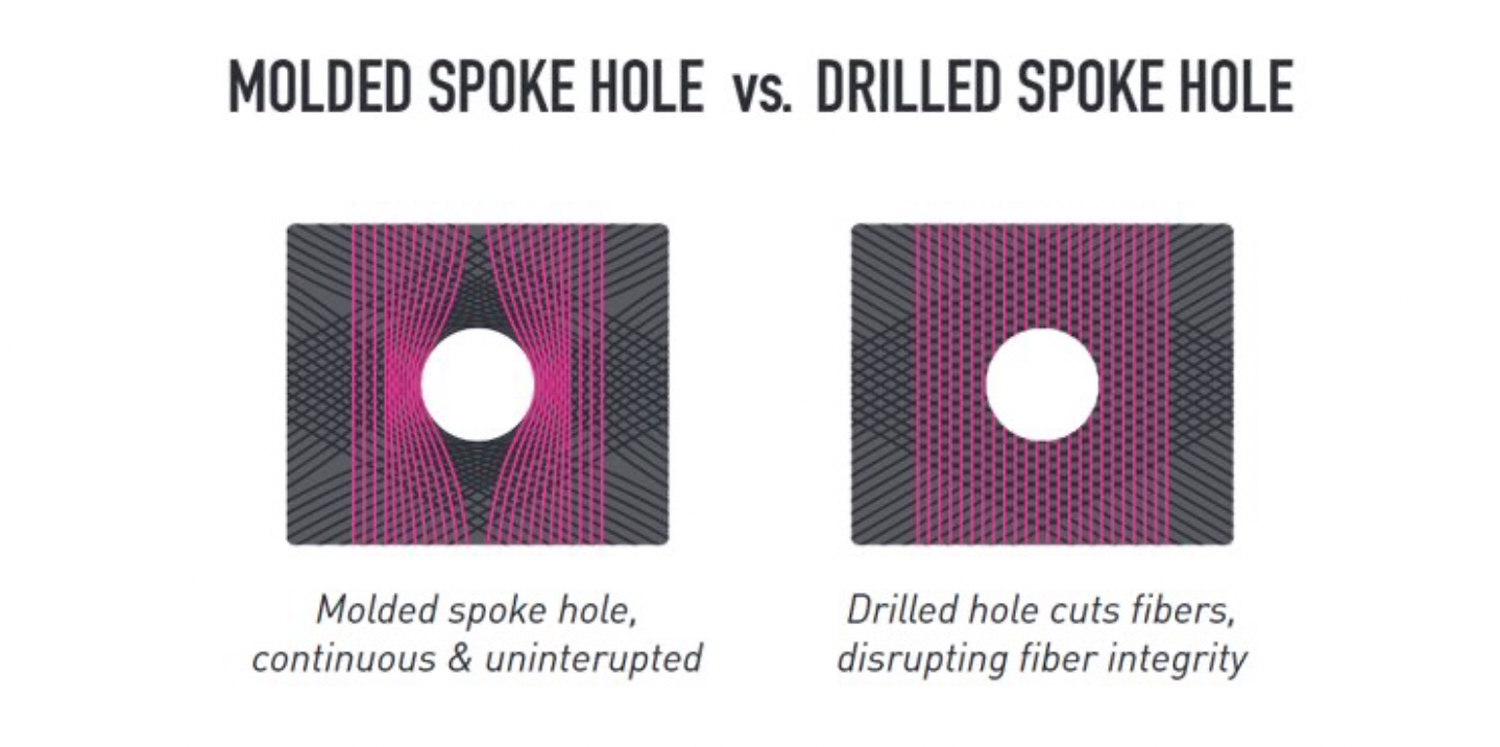

Molded Spoke Holes (Patented): ENVE routes carbon fibers around the spoke holes instead of drilling through them. Result: stronger spoke holes that hold higher tension and reduce the risk of spoke pull-through. In theory, this results in less wheel truing over the life of the wheel.

INNERDRIVE Hubs: ENVE’s own design with oversized 42 mm ratchets positioned inboard over the bearings. The Foundation version uses high-performance steel bearings (the Premium hubs use stainless steel) with the same seal strategy. Components are interchangeable if you ever want to upgrade.

TRADE OFFS.

This $1,400 dollar wheel looks the same as, say, the SES 4.5, but what really is the difference?

It’s in the little things that save costs and add a little weight like steal bearings instead of stainless steel; brass nipples instead of alloy; J-Bend spokes instead of Alpina Ultralite Aero R5 with TCX 2/1.5/2. This is the equivalent of SHIMANO 105 instead of Dura-ACE. But it’s still SHIMANO. It’s still ENVE.

HOOKLESS

This is a hookless rim. That means you need tubeless-compatible tires designed for straight-sidewall (TSS) rims. The good news is that’s where all the tire R&D money is going these days. The modern performance tire is tubeless. This will, of course, turn some older dogs away. But it does illustrate where the market is still heading, or at least being directed to head. This will now be at least the third OEM-priced wheelset that is hookless. ZIPP and SYNCROS being the other two brands I consider as offering strong OEM wheel offerings at mass in the marketplace.

This also brings me to my next point on tire size. You will want to take into consideration before you purchase the minimum tire size of 27 mm. So, if you’re the type of rider that still thinks 25 mm is “faster,” then look the other way. And start buying up all those clearance tires. With this wheel, of course, ENVE wants you to use the “Approved/Recommended” tires that you can find on ENVE’s Tire Compatibility Page. And I do find it interesting that they seemed to have gone away from the “72” max pressure level, giving the minimum tire (27 mm) an 80 psi / 5.5 bar limit. (Which will still feel hard as rock.) This goes to show you the level that tire companies are starting to get to with TUBELESS/ HOOKLESS beads. Tires are just built better now.

The Elephant in the Room: Manufacturing

Here’s something ENVE isn’t leading with in the marketing materials, but it’s an important detail. The AR40 is NOT being produced at ENVE’s Ogden, Utah facility. In fact these wheels are the company’s first to be manufactured off sight. This is not because of margin goals—it is more about a lack of manufacturing ability onsite at the moment. It goes without saying that, when you create great products, and you just happen to have that product being used by the best cyclist in the world, sales follow. And, at this time, ENVE really can’t keep up at home. So, while they created this wheel from scratch, it will not be made in Ogden as they have dedicated “all hands on deck” to the current premium wheels that require that extra hands-on touch. I would like to point out that in my conversation with the folks at ENVE, they made it very clear that ENVE owns this wheel and its production overseas from start to finish. And, according to them, this is not a “first move” to take manufacturing overseas.

My thoughts

While I havent had a chance to ride this wheel (yet), I have seen it, and I’m liking what I see. It’s got that ENVE look, touch and feel. The AR40 fills a gap in ENVE’s (and the community’s) line up. This all-around 40 mm-depth aero carbon wheel, with modern width, gravel capability and actual wind tunnel data behind it, comes at a price point that doesn’t require a second mortgage. Whether the aero claims hold up in the real world remains to be seen, but at least they’re showing their work with the testing. And they did it comparing apples to apples on “wider wheels” in the market.

| Wheel Options | Price |

|---|---|

| Front Wheel, 12×100 | $630 |

| Rear Wheel, HG Freehub, 12×142 | $770 |

| Rear Wheel, XDR Freehub, 12×142 | $770 |

| Rear Wheel, Microspline, 12×142 | $770 |

All wheels feature a centerlock disc and come ready with tape and valves. There is a 24-spoke count for both the front and rear, with Sapim CX-Ray J-bend spokes.