Hey the slowtwitch hive mind, I’ve got a Vision trimax sI013 aerobar set-up with the vision deep pads run as narrow as possible, but want to try to run a BTA bottle. There’s a bridge between the arm cups as part of the bars, I wondered if this was something I could replace with a 3D printed or machined part that fits in using the existing bolt holes but has a built in riser for me to mount a cage on above my arms a la revolver do or as Sam Long kinda runs but more DIY. Is this something feasible, or am I forgetting some crucial detail that will scupper my plans? Any help/suggestions/random factoids or opinions welcomed

I have had success with nylon spacers and longer bolts from the hardware store. I have also bent aluminum stock from lowes to make an upside down “u†shaped bridge that I mounted the bottle cage on.

Wolf tooth has some accessories that may work. Worth checking out.

I used some 3t aerobar risers. As rare as hens teeth in their own right now, but something like https://www.wiggle.co.uk/prime-noosa-tt-aero-handlebar-riser-kit will probably work

I used some 3t aerobar risers. As rare as hens teeth in their own right now, but something like https://www.wiggle.co.uk/prime-noosa-tt-aero-handlebar-riser-kit will probably work

Did you use these?

https://mybikeshop.com/products/3t-vola-pro-riser-kit-10mm-20mm.html?sku=20330109

I am in a similar situation - would be curious to see other folks set up.

MrTri123 - I feel really dumb, well dumber than usual, but how would you use those pieces to raise a bottle cage? Maybe I need more coffee this morning, but the ‘arch’ piece would pose some difficulty?

I am in a similar situation - would be curious to see other folks set up.

MrTri123 - I feel really dumb, well dumber than usual, but how would you use those pieces to raise a bottle cage? Maybe I need more coffee this morning, but the ‘arch’ piece would pose some difficulty?

Sorry I have no idea lol

I was asking the person who talked about them

HA - my bad - totally misread your response!

I used some 3t aerobar risers. As rare as hens teeth in their own right now, but something like https://www.wiggle.co.uk/…-handlebar-riser-kit will probably work

Did you use these?

https://mybikeshop.com/...mm.html?sku=20330109

No, these.

https://www.probikekit.co.uk/…-30032/10943872.html

I made something exactly like this for my aerobars.

The armcups are a ‘monopad’ I made myself from carbon fibre. I also drilled holes in the middle to attach the bottle holder to. The orange part is a 3D printed spacer to get the bottle in the correct position. I tried several sizes to make sure I don’t bump my chin to the bottle, yet I can get my head low enough.

If you have (access to) a 3D printer and bolts, it should be relatively simple. Do you have holes in the middle of the aerobar bridge for attachment?

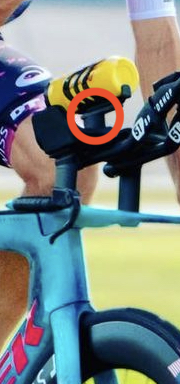

no, the bridge bolts in between the arm rests either side, I was wondering if printing a part that could have the spacer for the cage like you have bolted into a bridge a person I know has printed that replaces the current one. You can see the bridge part I’d replace in the photo below from this article Vision Trimax Carbon SI 013 - Slowtwitch.com (I’ve got these bars but high sided arm cups on instead Vision R25 armrest | VISION (visiontechusa.com))

(the best photo I’ve got to hand showing arm cups/lack of space between them)

Yes you could replace the bridge for a 3D printed one with the BTA mount integrated, that is a neat solution.

Keep in mind that, when the bridge is replaced by a 3D printed version, it looses its structural/stability function. I am not sure how the aerobar is designed, this might be a bad/unsafe thing to do.

If so, you could design a 3D printed bottle holder that clamps around your bridge, to keep the bridge original

Hey Timmetje,

great setup! Could you please provide some more information about your custom monopad?

I was thinking about doing something similar and found a “memory-carbon-plate” which is shapeable with a heat gun.

Did you use something like this?

Best,

Julian

Hi Julian,

I am not familiar with this memory plate you mention.

I first made a mould using a foam material. I cut two wooden boards to define the shape, then used a hot wire to cut the foam to this shape (see below).

Then, I used vacuum infusion to make the carbon U-shape. At the time I worked at a company designing all kinds of carbon composite products, so I had access to the material and equipment. However, this can also be done relatively simply using a wet lay-up process.

Afterwards, it was cut and sanded to shape. I used a foam from aliexpress which is kept in place using double sided tape.

Let me know how you get on ![]()

PS sorry for the large photo size

I am searching for this exact same thing for my SC. I wonder what Sam L uses as well?

Most of the Trek pros have had theirs made by Trek (Rudy confirmed for his). So far I have resorted to long M5 screws and some nylon spacers as someone else mentioned above. It’s working OK, not the neatest but is a good first step to figure out the best positioning before having a printed adapter made.