The current state of front ends in the tri/tt world for the average age grouper is a complete cluster fuck right now.

Yup, I’d love to see the demise of “proprietary cockpits”. Even proprietary Seatposts. Luckily for me, it looks like there is a lot of Scott DNA in this frame - I swear that’s a Plasma 3 seatpost, which until now have been made out of unobtanium.

I was going to say it looks very very similar to the Scott plasma three from over 10 years ago…Sebastian Kienle’s Plasma 3 - Slowtwitch News

Any insight on what he is using the front “The Feed” bottle for? Looks like he cut out a panel and will use it as bento box of sort?

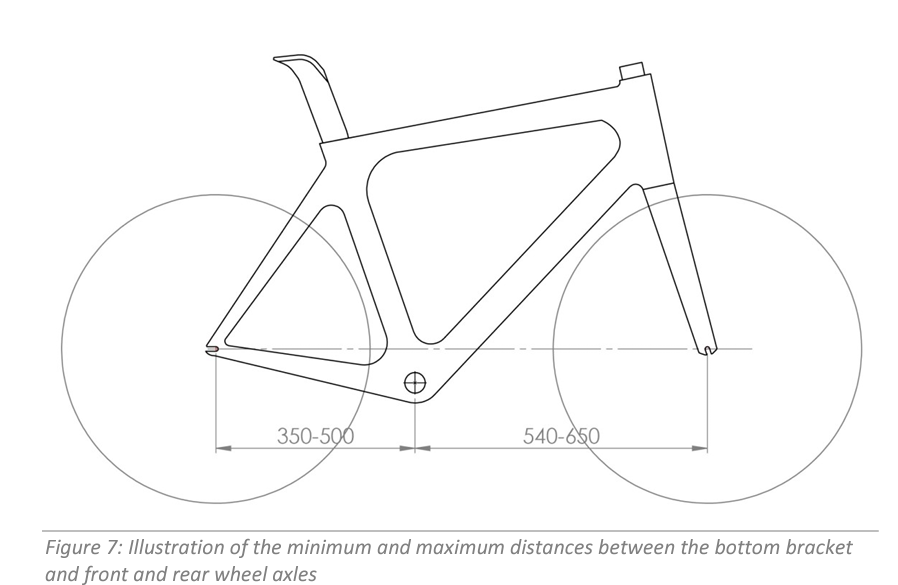

From our dear friends at the union of creativity inhibition (UCI), article 1.3.016

Front Centre is usually measured directly from bb to hub, so 653/654 is the practical limitation. Thus a 61 P3 MKI & II, were not UCI legal. The P-Series got shortened so it is in that size.

Thus we see that a 443mm frame x with a 72.5deg HTA is as long as a bike can be within the UCI rules. Of course, if you chopped the head tube by 40mm you could have a 455, 548(y) frame.

World Triathlon uses the UCI rules. So now, do USAT.

Ironman have the same rule, but with an exception

So Ditlevs bike is only legal for IM races, not T100 and World Tri long course.

The new Ventum has been designed to give them access into cycling, so they couldn’t push the rule. Cervelo straddle both worlds so they stick to the rules.

Then for a small brand that focuses on Tri - yes they could make a 680 FC bike, but their sales would be so low that they’d never pay off the moulds. Thus we don’t get any innovation in frame geometry.

So it does become the component manufacturers issue. Because triathletes are trying to do weird things to UCI based frame geometries.

And the issue there is that it just takes time. Design iterations, mould making, testing, mould revisions, more testing, production etc. It’s easy if you 3D print or CNC something and send it out into the world with no testing or just at a rudimentary level. But when you get serious about safety you get down to “oh, the thickness and type of lacquer on the carbon extension makes a difference to bracket durability” which takes time.

Anyone that makes basebars has nightmares about what people are doing with reach extenders. On the BMC Speedmachine I helped them plan out two basebars to allow for the extra reach that I predicted riders would be using… and still that wasn’t enough. Riders are testing the boundaries, so as soon as they get more allowance they max it out.

But back to the Ventum. The stock kit will be the massively adjustable AU Std bracket - which makes life easy to fit the vast majority of riders. Then the AU Race bracket suits narrower pad positions. Both work with the reach extender and tilt booster.

The ASC Pro gives a one piece solution (for a more limited set of riders) and can use the reach extender.

Jasons aero testing showed a nice advantage for the ASC Pro. And no risks to his safety.

I saw that too! Looks like a Maurten caffeine gel and or some other nutrition item(s) for storage.

behind the saddle : B-RAD Double Bottle Adapter – Wolf Tooth Components

between the arm : https://www.cervelo.com/_next/image?url=https%3A%2F%2Fimages.prismic.io%2Fcervelo%2FZn7q5h5LeNNTwooW_Z8C_1197--1-.jpg%3Fauto%3Dformat%2Ccompress&w=2100&q=75

(the other hole is in the angle part)

No, 6.7. can be ride with 25, they are less wide than 3.4 or 4.5