Triathlon Forum

Login required to started new threads

Login required to post replies

Re: The ultimate DIY disc wheel cover how-to thread. [stef32]

[ In reply to ]

Re: The ultimate DIY disc wheel cover how-to thread. [undertheradar]

[ In reply to ]

Need graphics for your covers?

Im in Orange county, Cypress area and have a printer 54" wide Eco-Solvent inks, full color, if interested please reply back!

Thanks,

Checko Ayala

Im in Orange county, Cypress area and have a printer 54" wide Eco-Solvent inks, full color, if interested please reply back!

Thanks,

Checko Ayala

Re: The ultimate DIY disc wheel cover how-to thread. [undertheradar]

[ In reply to ]

Hey there friend!!!! I'm located in SoCal to and I'm trying to do this to my bike as well! But I have a few questions, can you help me? :)

Re: The ultimate DIY disc wheel cover how-to thread. [undertheradar]

[ In reply to ]

Thanks for this great tutorial. I finally got around to making mine yesterday. The hardest part was cutting the discs as my abs came in a single sheet.

I made 3 loops on the back of each disc using spare abs, about 3" long and 1/2" wide. I glued these down with a chopstick slid thru the middle of each one to provide some clearance. Once I put both covers on, I ran a zip tie thru the straps which pulls both covers together. Worked pretty well.

the only thing that will make me faster now is some flames painted on the cover.

I made 3 loops on the back of each disc using spare abs, about 3" long and 1/2" wide. I glued these down with a chopstick slid thru the middle of each one to provide some clearance. Once I put both covers on, I ran a zip tie thru the straps which pulls both covers together. Worked pretty well.

the only thing that will make me faster now is some flames painted on the cover.

Re: The ultimate DIY disc wheel cover how-to thread. [Ellsworth81]

[ In reply to ]

anyone have a picture of a cover made with Hi-Impact Styrene? would 0.02'' or 0.03'' be recommended?

Re: The ultimate DIY disc wheel cover how-to thread. [undertheradar]

[ In reply to ]

I just made some disc covers for my wheels. The plastic I found was .045 thick. I got them made and installed and noticed they wheels seemed pretty heavy. So I weighed the wheels and the wheel, cassette, and cover weighed in at 6 lbs. I thought that was a lot. I weighed just one cover and it weighs 14- 15 oz. So that means I'm adding 2 lbs to the rear wheel and to the total bike weight. I was curious if there was a point that the weight out weighs the aerodynamics of the cover. I rode the bike this morning and I couldn't tell any difference but it was just one ride. Anybody have any suggestions...I guess I just need a stronger engine for the bike.

Re: The ultimate DIY disc wheel cover how-to thread. [cruiserguy73]

[ In reply to ]

The weight won't slow you down unless you are climbing... and then not a lot.

Re: The ultimate DIY disc wheel cover how-to thread. [rruff]

[ In reply to ]

I tried this out with cardboard and package tape, worked fine on the none drive side. On the ds I had either not a smooth surface from taping to the spokes or chain and rd contact when on the highest cog.

Did anyone try to warm up the plastic to avoid the cutting and cementing process?

And yes....the weight is another thing I'm focused on cause of kinda hilly courses I have around for training and even racing.

-shoki

Did anyone try to warm up the plastic to avoid the cutting and cementing process?

And yes....the weight is another thing I'm focused on cause of kinda hilly courses I have around for training and even racing.

-shoki

Re: The ultimate DIY disc wheel cover how-to thread. [shoki]

[ In reply to ]

I did some investigating of this lately. Looks like you can get black high impact styrene in thinner sheets like .02" but I'm not sure how thin you can go and still have it work well. The ABS I'm using is .04".

I think you'd have a really tough time getting a smooth surface by heating the plastic... but who knows. The trick is to make the cone just right so you don't have to distort it to make it fit flush.

I think you'd have a really tough time getting a smooth surface by heating the plastic... but who knows. The trick is to make the cone just right so you don't have to distort it to make it fit flush.

Re: The ultimate DIY disc wheel cover how-to thread. [rruff]

[ In reply to ]

That I know. I was just thinking to avoid anything payed in there extra (like the stripe for glueing) because of the wheel maybe not true anymore, but maybe I'm throwing the ball too far.

-shoki

-shoki

Re: The ultimate DIY disc wheel cover how-to thread. [rruff]

[ In reply to ]

I'm using .03 ABS plastic on the wheel covers that I make. To be honest, and I know a lot of people may disagree but in my

opinion the "overlap" caused is not noticeable at all. Yes it is more noticeable in the .04 but in the .03 it really isn't. I can't believe

that the wind could tell the difference.... Cutting out the overlap is not a big deal either but not really needed.

I have not tried .02 plastic of any kind but I have to think it'd be a bit too flimsy. I think the .03 that I use is the best for a

DIY disc wheel cover.

As far as using high impact polystyrene I've tried it but it's not really good for a long term application. It's good to use for prototypes and

I do, but not for a disc cover that will last for several years. Maybe getting it wrapped would be cool and that would help

make it a bit more hardy but that would be a bit spendy unless you could do that yourself.

Find out what it is in life that you don't do well, then don't

do that thing.

opinion the "overlap" caused is not noticeable at all. Yes it is more noticeable in the .04 but in the .03 it really isn't. I can't believe

that the wind could tell the difference.... Cutting out the overlap is not a big deal either but not really needed.

I have not tried .02 plastic of any kind but I have to think it'd be a bit too flimsy. I think the .03 that I use is the best for a

DIY disc wheel cover.

As far as using high impact polystyrene I've tried it but it's not really good for a long term application. It's good to use for prototypes and

I do, but not for a disc cover that will last for several years. Maybe getting it wrapped would be cool and that would help

make it a bit more hardy but that would be a bit spendy unless you could do that yourself.

Find out what it is in life that you don't do well, then don't

do that thing.

Re: The ultimate DIY disc wheel cover how-to thread. [elpete]

[ In reply to ]

did I miss how this cover was attached to the wheel besides the shipping tape? If the disc isnt secure that could turn into a pretty hairy situation.

Re: The ultimate DIY disc wheel cover how-to thread. [Theo911]

[ In reply to ]

They run high quality 3M electrical tape round the cover/rim join.

-------------------------------

´Get the most aero and light bike you can get. With the aero advantage you can be saving minutes and with the weight advantage you can be saving seconds. In a race against the clock both matter.´

BMANX

-------------------------------

´Get the most aero and light bike you can get. With the aero advantage you can be saving minutes and with the weight advantage you can be saving seconds. In a race against the clock both matter.´

BMANX

Re: The ultimate DIY disc wheel cover how-to thread. [Theo911]

[ In reply to ]

Theo911 wrote:

did I miss how this cover was attached to the wheel besides the shipping tape? If the disc isnt secure that could turn into a pretty hairy situation.the easy way to do that is to duct tape the cover to the spokes on one side and use double sided duct tape around the hub

area on the other side. I've done that for a long time and I've never had a problem.

edit: and of course you use 3M Super 88 electrical tape around the perimeter of the disc.

Find out what it is in life that you don't do well, then don't

do that thing.

Last edited by:

pattersonpaul: Oct 30, 13 14:01

Re: The ultimate DIY disc wheel cover how-to thread. [pattersonpaul]

[ In reply to ]

Sounds like you know something about plastic. Why is high impact styrene no good? Is ABS better than nylon?

I'm not even seeing large sheets of .030 ABS online anywhere. Do you remember where you got it? I bought from Tap Plastics before, but the thinnest they list now is .060.

I'm not even seeing large sheets of .030 ABS online anywhere. Do you remember where you got it? I bought from Tap Plastics before, but the thinnest they list now is .060.

Re: The ultimate DIY disc wheel cover how-to thread. [rruff]

[ In reply to ]

Polystyrene plastic is used to make cheap temporary signs mainly for indoors and also for prototype projects, that's what I'm told.

ABS plastic is bit more sturdy and won't break down with sunlight nearly as quickly as polystyrene.

I really don't know much about plastic other than for making disc wheel covers. I will be happy to send you

some ABS plastic in the .03 thickness, enough for you to experiment with to make a disc wheel.

Tap Plastics and most other plastic mfg companies don't carry .03 much. I guess there's not that much

of a call for it.

Find out what it is in life that you don't do well, then don't

do that thing.

ABS plastic is bit more sturdy and won't break down with sunlight nearly as quickly as polystyrene.

I really don't know much about plastic other than for making disc wheel covers. I will be happy to send you

some ABS plastic in the .03 thickness, enough for you to experiment with to make a disc wheel.

Tap Plastics and most other plastic mfg companies don't carry .03 much. I guess there's not that much

of a call for it.

Find out what it is in life that you don't do well, then don't

do that thing.

Re: The ultimate DIY disc wheel cover how-to thread. [Theo911]

[ In reply to ]

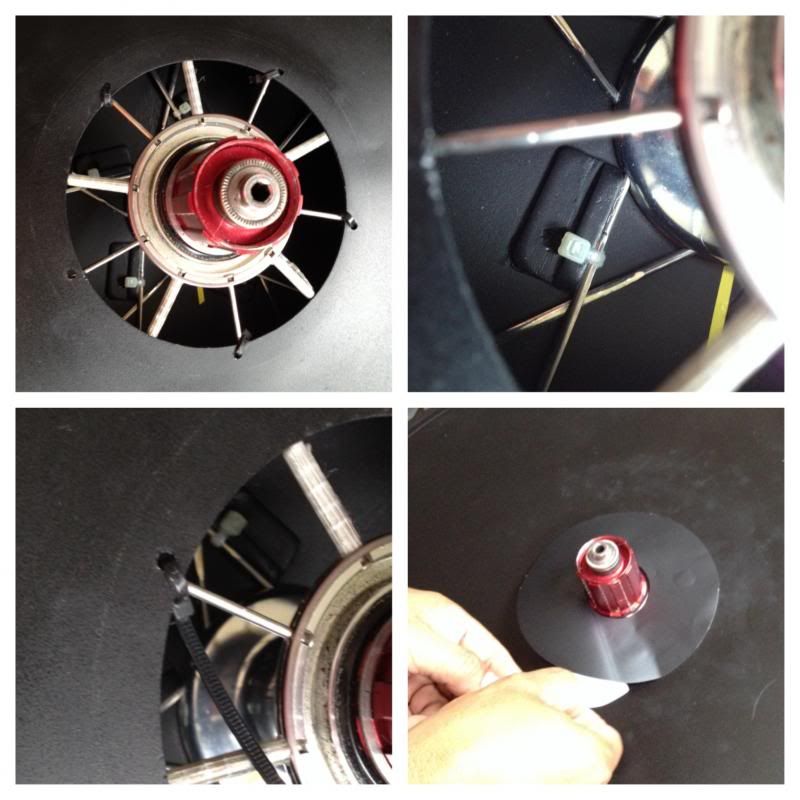

I experimented on my own disc cover using abs plastic.

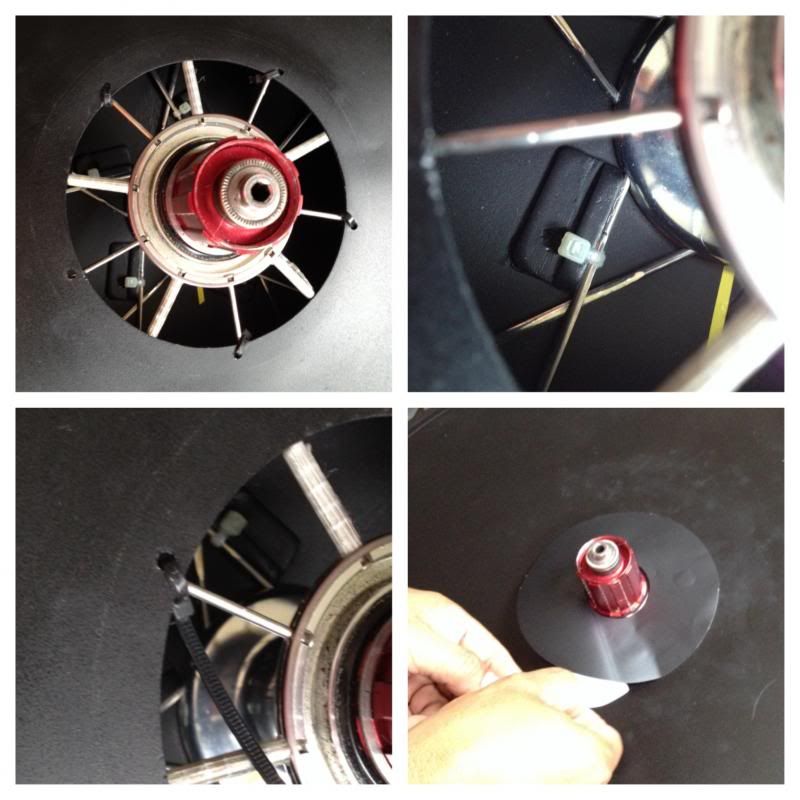

I made a hole on the drive side just the size of the biggest cog so cover removal doesn't need cog removal.

Then I made a round sticker sheet to cover the hole drive side.

I didn't like the screws and the waves that come out sometimes.

To eliminate the screws, I made the non drive side have small grommets to zip tie on the spokes.

Then I install the drive side with small holes around the sprocket hole to zip tie drive side.

Then I use McCall matte decals to fix around the rims. Using a little hair dryer makes the bond better.

Removal needs some work, sticker replacement & zipp tie cutting.

But I like the clean look when in place, no screws, no waves.

Came out with a cleaner look.

I can remove with cog in place, replace the stickers & zip tie.

Added about 130g to my 808FC.

Much cheaper than buying a whole new Super 9.

Still no wok wok wok sound of a real disc.

I made a hole on the drive side just the size of the biggest cog so cover removal doesn't need cog removal.

Then I made a round sticker sheet to cover the hole drive side.

I didn't like the screws and the waves that come out sometimes.

To eliminate the screws, I made the non drive side have small grommets to zip tie on the spokes.

Then I install the drive side with small holes around the sprocket hole to zip tie drive side.

Then I use McCall matte decals to fix around the rims. Using a little hair dryer makes the bond better.

Removal needs some work, sticker replacement & zipp tie cutting.

But I like the clean look when in place, no screws, no waves.

Came out with a cleaner look.

I can remove with cog in place, replace the stickers & zip tie.

Added about 130g to my 808FC.

Much cheaper than buying a whole new Super 9.

Still no wok wok wok sound of a real disc.

Re: The ultimate DIY disc wheel cover how-to thread. [campled]

[ In reply to ]

Looks nice. Not seeing any seam at all... it does have a seam? What thickness of ABS is it?

Re: The ultimate DIY disc wheel cover how-to thread. [rruff]

[ In reply to ]

Its a .3 thick abs.

Painted matte over it, you can see it slightly at about 2:00 of the non drive side pic.

Painted matte over it, you can see it slightly at about 2:00 of the non drive side pic.

Re: The ultimate DIY disc wheel cover how-to thread. [campled]

[ In reply to ]

that looks really good -- I like the zip tie attachment.

Then I made a round sticker sheet to cover the hole drive side.

Sure you can remove it without removing the cogs, but if you want to put a new sticker on when you re-install it you need to take off the cassette.

campled wrote:

I made a whole on the drive side just the size of the biggest cog so cover removal doesn't need cog removal. Then I made a round sticker sheet to cover the hole drive side.

Sure you can remove it without removing the cogs, but if you want to put a new sticker on when you re-install it you need to take off the cassette.

Re: The ultimate DIY disc wheel cover how-to thread. [asad137]

[ In reply to ]

The cog hole sticker has a line cut.

I can maneuver the sticker around the cog & press in place with a popsicle stick.

A bit of a hassle but the best I could think of for now.

I can maneuver the sticker around the cog & press in place with a popsicle stick.

A bit of a hassle but the best I could think of for now.

Re: The ultimate DIY disc wheel cover how-to thread. [campled]

[ In reply to ]

Very nice, Wheel Builders should hire you. In my experience the only way you can get the "real disc" sound is to have the disc

wheel covers bonded to the spokes. And by bonded I mean pretty much 100%.

I've used foam insulation spray to do that and it works pretty well. Obviously not something that you'd want to do with an expensive

rear wheel like you have there. Try it with a cheap training wheel and some DIY ABS covers.

The only thing about doing that is when the disc covers are melded together with the wheel on a sunny and hot day the black covers will

warp caused by heat deflection. You can paint them silver, grey or white and it won't do that too badly.

Very smart solution you have there.

Find out what it is in life that you don't do well, then don't

do that thing.

wheel covers bonded to the spokes. And by bonded I mean pretty much 100%.

I've used foam insulation spray to do that and it works pretty well. Obviously not something that you'd want to do with an expensive

rear wheel like you have there. Try it with a cheap training wheel and some DIY ABS covers.

The only thing about doing that is when the disc covers are melded together with the wheel on a sunny and hot day the black covers will

warp caused by heat deflection. You can paint them silver, grey or white and it won't do that too badly.

Very smart solution you have there.

Find out what it is in life that you don't do well, then don't

do that thing.

Last edited by:

pattersonpaul: Nov 5, 13 7:06

Re: The ultimate DIY disc wheel cover how-to thread. [campled]

[ In reply to ]

Very clean. I like the grommet idea. Thumbs up.

-shoki

-shoki

Re: The ultimate DIY disc wheel cover how-to thread. [shoki]

[ In reply to ]

that looks great--are the grommets glued to the abs? can you explain more in detail how the cover is attached to the wheel at the edges? electrical tape?

Non drive side

- one hole cut, cone shaped.

- grommets glued to inside near hub at 5 points.

- grommets attached to wheel zip tied to spoke

Drive side

- two hole cut, inflation & cog hole.

- almost flat shape

- cog hole almost same size as biggest cog.

- 5 small holes made near cog hole for zip ties.

- After zip tie attached & cut, sticker installed to cover cog hole.

Start with non drive side.

After both are zip tied, I cut a 2cm wide strip from a sheet of matte tape (McCal brand).

I tape the ends to the rim, forcing the circular path from the straight matte tape.

I blow dry the tape to make it conform to the rim & have better adhesion.

Will try it this weekend, passing over rough sections to see how well it stays together.

- one hole cut, cone shaped.

- grommets glued to inside near hub at 5 points.

- grommets attached to wheel zip tied to spoke

Drive side

- two hole cut, inflation & cog hole.

- almost flat shape

- cog hole almost same size as biggest cog.

- 5 small holes made near cog hole for zip ties.

- After zip tie attached & cut, sticker installed to cover cog hole.

Start with non drive side.

After both are zip tied, I cut a 2cm wide strip from a sheet of matte tape (McCal brand).

I tape the ends to the rim, forcing the circular path from the straight matte tape.

I blow dry the tape to make it conform to the rim & have better adhesion.

Will try it this weekend, passing over rough sections to see how well it stays together.